Global Leader In Brewery Equipment Solutions

Fully automatic turnkey beer system to meet the different process choices of different brewers. We supply perfect beer equipment design and personalized custom brewing solutions. We subject each brewing system to stringent testing procedures before launching them in the market.

Fully automatic turnkey beer brewing system to meet the different process choices of different brewers.

Hgmc can provide you with all sizes commercial beer brewing equipment, devices from 1BBL to 100BBL.

Hgmc knows for its high quality and long-term customization experience. We can provide customized services for brewery equipment.

Of course, we will also provide turnkey product solutions for breweries.

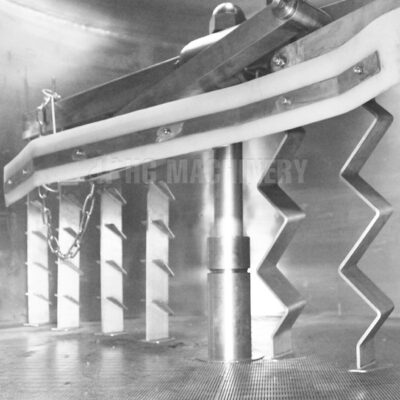

Details For Beer Brewing Equipment

Beer Brewing Equipment Advantages

- Equipment design as per customer brewing method and brewing beer types can make beer highest to 33 Plato.

- Energy saving, higher brewing efficiency and lower material consumption, higher wort wort extract

- Fully automatic mash, wort, water flow and automatic temperature control

- Well designed steam system to increase heating efficiency and lower energy lost

- More reasonable piping construction to avoid the wort aeration problem and decrease the material lost

- Specially designed jackets on both body and cone to ensure heating and cooling efficiency

- Bigger headspace, the cover headspace volume is calculated separately and extra.

- 100%TIG welding process to weld the tank, jackets welding are all full welding by water, uniform dimpled cooling jacket to ensure no leaking and long life, welds passivated!

- Overall mirror polishing, polishing 6 times to make Ra 0.4um mirror finish, can clean 360° without dead ends.

- Jacket testing 12 hours with air and water, jacket testing pressure is 5Bar, internal shell testing pressure is 4Bar, and before packing we will also have 48hours of water testing.

- Strict quality control and process inspection & testing system, which all the testing record will show on our data late with the tanks shipping, with checking the list and serial numbers to track.

- Insist on a high-end product line to manufacture our tanks, all components like chiller, exchanger, steam boiler, and Schneider/ABB electronics control systems all adopt international brands to ensure quality and convenient after-sales.

Standard Configuration For Beer Brewing Equipment

Malt Milling Unit

- Particle adjustable rolling crusher

- Flexible or steel auger to directly lift the milled grain to mash tun

Brewhouse Unit

- Mash, Lauter, Boiling and Whirlpool tun in variable combination

- Hot water tank and cold water tank for optional in special combinations

- Infusion or decoction brewing methods are designed exactly

- Boiling process can be done under pressure, especially for brewery at higher altitude

- Two stages or a single-stage heat exchanger for wort cooling

- Completely stainless steel integrated work platform

- Sanitary and efficient wort pump

- All pipings and fittings

Fermentation Tank Unit

- Standard stainless steel conical cylindrical fermentation tanks

- Standard stainless steel bright tanks for beer maturation, conditioning, carbonation

- Single size or double size as brewhouse is commonly used in microbreweries

- Tanks quantity is exactly calculated by fermentation cycle for various beers

- All manhole, valves, pressure gauges, fittings, etc are included

Cooling Unit

- Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing

- Efficiency chillers or refrigerators with freon to supply cooling energy

- Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

- More energy saving solution with HLT water recycle use and CLT for wort cooling

Controlling Unit

- PID control system with temperature, on-off buttons for motor/pumps, valves manually

- PLC semi-automatic control system with pneumatic valve, automatic temperature, mixing of feeding water, accurate measurement of sparging water, automatic liquid level, automatic brewing process control

- PLC fully automatic control system with curve indication and production record printing, with recipe storage function, clients can create new recipe as the exact production requirement

- Fully automatic grains out is optional according to the sizes of the system

Brewery Application Case

Frequently Questions

We offer comprehensive after-sales services, including equipment installation, commissioning, operator training, maintenance support, and spare parts supply. Our dedicated service team is always ready to provide technical support and solutions.

Yes, we provide long-term maintenance services for our equipment. We offer regular inspections, maintenance, and troubleshooting services to ensure your equipment is always operating at its best.

Yes, we offer international shipping services. No matter where you are located, we can arrange efficient and secure shipping to deliver the equipment to your facility on time.

Our equipment undergoes strict quality control procedures, using high-quality materials that meet international standards. Multiple tests are conducted during production, and all equipment is thoroughly tested before leaving the factory to ensure performance and safety.

Delivery time generally depends on the type of equipment and customization requirements. Standard equipment typically takes 4-6 weeks for delivery, while custom equipment may take 8-12 weeks. We will provide a detailed delivery timeline based on your specific needs.

You can fill out the contact form on our official website or directly reach out to our sales team for more information or a quote. We will provide detailed technical specifications and a quotation based on your needs.

Get in touch

Turnkey Solutions for your Brewing Process

Head office

Huixin Times Center, No. 2228 Tianchen Road, Jinan, China

Email us

Telephone

+86 531 86418866

+86 18006415555

Contact information

Speak with a sales representative during normal business hours (Monday – Friday, 8:30am – 5:30pm UTC+8).

Send us a message