Co2 recovery plants for brewery

Co2 recovery plants for brewery , Recovery units are designed to collect and utilize the CO2 generated during the brewing fermentation process.

The plant promotes a circular utilization of the brewery’s CO2 by recovering the CO2 from fermentation. It is collected, purified, liquefied, stored, and ready to be used in all steps of beer production.

As a complete CO2 recovery system, the plant reduces the brewery’s CO2 emission and gives a reliable and cost-efficient supply of CO2 – making your brewery more suited for the future.

CO2 Recovery Process Overview

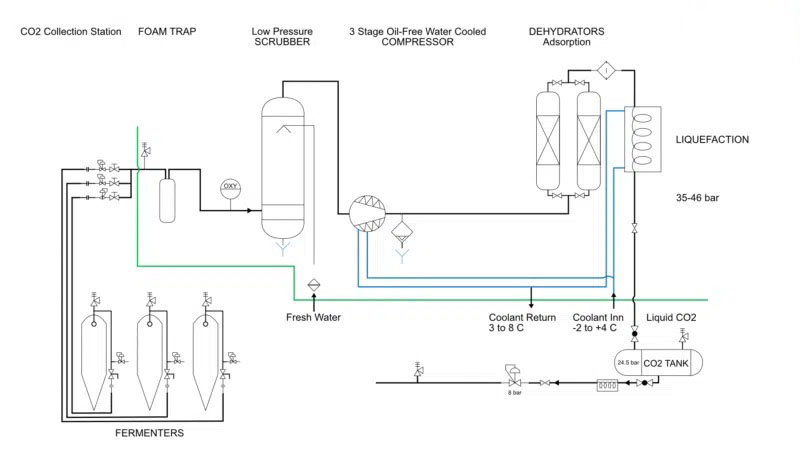

CO2 collection

The raw form of CO2 is collected from the fermentation tanks using flexible hoses connected to the existing tank’s CIP/gas outlet and to one of the central CO2 collection stations connection points.

Each of the connection points is equipped with a bunging valve or a check valve, and a shut off valve to ensure individual and continuous system operation without risk of cross contamination. If individual fermentation pressures are needed, bunging devices must be used instead of check valves.

CO2 purification

The purification takes place in 3 steps before and after compression and liquefaction. The CO2 raw gas from the collection system is supplied to the foam trap where the foam is seperated. After the foam trap but before the CO2 gas reaches the compressor, 90% of the impurities like alcohol, other volatiles and aerosols, are removed in the water scrubber. After compression the gas is dried and further purified in aluminium oxide-based dehydrators, which also removes traces of remaining volatiles. The Dehydrator is duplicated and regenerates automatically by heating. If needed an activated carbonfilter can be installed for H2S removal. To remove incondesabler gases, the liquied CO2 is destilled in the HGMC patented condenser and in a small reboiler and stripper column.

Liquefaction

The CO2 is compressed to be liquefied for rectification and compact storage and unlike conventional CO2 compressors, The HGMC three stage CO2 Compressor provides up to 45 bar pressure, hence the CO2 condensation takes place at 0-5 degree Celsius. This makes it unnecessary to use a separate CFC or ammonia cooling systems, but a glycol, ice-water or alcohol coolant system can be.

The dry and compressed CO2 is liquefied in in the condenser using an external coolant source and the liquid CO2 is continuously distilled to ensure low oxygen content. Liquid CO2 is pushed with 35-40 bar pressure to the CO2 storage tank, where liquid CO2 expands to the storage tank pressure and temperature. Vaporized CO2 from the storage tank is sent back to the compressor.

CO2 Storage and usage

HGMC offers a wide range of storage tanks from 100 liters to 50 tons and all tanks delivered from DALUM is adapted for CO2 recovery including high pressure storage option to reduce vaporization, flash gas return function, seperate CO2 filling line for low loses, chiller option and integrated ambient or glycol regenerable vaporizers.

HGMC can also take care of nessecary filters, regulators and safety devices for userlines. For breweries filling sparkling water using recovered or industrial CO2, DALUM always recommend to use final polishing filters after vaporizer and line regulator as the final step before a sterile filter and usage.

HGMC also offer cylinder filling stations designed to integrate seamlessly with our CO2 recovery plants and storage tanks, the station ensures smooth transfer of recovered CO2 into individual cylinders for further use or distribution.

Process Flow

FEATURES

Recovery units are designed to collect and utilize CO2 generated during the brewing fermentation process. The highest quality CO2 produced to meet stringent market requirements is ensured by using appropriate washing and filtration techniques.

The use of the most modern structured packing in the scrubber column allows reducing water consumption to 0.25 kg per 1 kg of finished CO2, which is equivalent to a 75% reduction in specific water consumption compared to traditional installations.

PUR-D technology is a final purification process, by means of a distillation column rectification process, which, in the process of separating and removing non-condensable gases, can reliably guarantee a reduction in the residual content of O2 < 5 ppm (volume) with a CO2 volume fraction of at least 99.998% .

The electrical system of the CO2 recovery unit consists of a decentralized electronic control panel and a low voltage power cabinet. The state-of-the-art electronic control panel allows you to monitor and control the operation of the unit in a color touch screen menu for easy access and trouble-free operation.

The unit starts automatically in sequence, and automatically maintains the operating mode. The whole process is easily monitored on the operator’s panel monitor, showing the status of the drives, readings of all sensors and alarms, which also have an audio accompaniment. All node-mounted instrumentation and A instruments are shipped unplugged at the factory and connected to remote module boxes.

The units are designed to provide the highest efficiency in 24/7 operation, durability, and the availability and reliability of individual components.

PARAMETERS

CO2 input (CO2 % vol.)

CO2 purity: ≥97%

Air source pressure: 0.003~0.005MPa

Air source temperature: up to 30°C

CO2 output (CO2 % vol.)

Regular: > 99.97

LO (Low Oxygen): > 99.998 / O2 < 5 ppm

HLP: > 99.998 / O2 < 5ppm

Brewery Application Case

Frequently Questions

CO2 recovery involves capturing and reusing carbon dioxide produced during brewing, reducing costs, lowering emissions, and enhancing sustainability.

Yes, CO2 recovery systems can be scaled to fit the needs of small breweries, offering tailored solutions that integrate seamlessly with their operations.

CO2 recovery reduces emissions, helping breweries comply with strict environmental regulations and avoid potential fines or penalties.

For this first brew you’ll need:

-

-

-

- A beer kit.

- A fermenting bucket.

- An airlock.

- A tap or siphon.

- A bottle stick.

- A long stirrer.

- Caps and a capper and some means to clean and sanitise your equipment.

-

-

As for our quality, all our raw materials used are stainless steel 304 or 316 material, the plate is all perfect 3mm and 2mm, some manufacturers with low prices, but they are 2.7mm.

Our factory have strict quality control and process inspection & testing system to make sure you get the quality you expect and delivery on time. Each of our orders shipment will have 5 inspection steps and the inspection record from materials in checking, production process, jacket pressure testing by water and air, finished product inspection and 48 hours water testing, equipment packing and loading inspection, finished product to the delivery and packing process, etc. Every of our tank will have the data plate with the pressure testing record and serial numbers to track. Testing 12hours with air and water, jacket testing pressure is 5Bar, internal shell testing pressure is 4Bar, and before packing we will also have 48hours water testing, which all these testing record will show on our data late with the tanks shipping.

Also for packing and shipping, we also have our strict standards, the shipping department will work out the checking list and pack them in wooden box, you will receive a checking list with everything we shipped.

The 10-barrel brewing system is equipped with heating methods, including electric, steam, and gas heating. HGMC also offers a variety of turnkey control methods.

The cost of a 10 BBL brewhouse chamber may vary depending on the function and specification of the glycosylation chamber. A basic, entry-level 10 BBL brewhouse chamber costs about $75,000, while more advanced high-end models can cost as much as $200,000.

Some factors that affect the cost of a 10BBL brewhouse chamber include the type of brewhouse chamber (e.g. electric, gas, or steam combustion), the type of brewing process (e.g. batch or continuous), the level of automation, and the type of finishing equipment (malting plant, granary, wort cooler, etc.).

By providing a consistent and pure source of CO2, recovery systems ensure uniform carbonation and flavor, leading to better-quality beer.

CO2 recovery significantly reduces a brewery’s carbon footprint by capturing and reusing CO2, contributing to global efforts to combat climate change.

Yes, the long-term savings on CO2 purchases, potential tax incentives, and increased customer loyalty make CO2 recovery a sound financial investment

We are manufacture of brewhouse in 2 vessel, 3 vessel and 4 vessel configurations and provide commercial brewery from 1HL to 500HL sizes for a wide range brewery needs.

This is not a question that can be answered very accurately, because every brewery has different requirements. If your brewery is too small, your space will be crowded. If your space is too large, you will waste a lot of money on startup costs and the space will not be well utilized. But we can provide you with some tips: 3BBL~5BBL brewery equipment needs about 300~500 square feet, and 7BBL~15BBL brewery equipment needs about 550~1200 square feet. Of course, if you need relatively accurate numbers, welcome to leave us a message.

Let’s take a common designed 10BBL beer equipment system as example,the list of the brewing system as below:

10BBL Mash/lauter tun

10BBL Kettle/Whirlpool tun steam heated

20BBL Hot water tank

3m3 wort pump and hot water pump

Stainless steel 304 wort pipes

10m2 plate heat exchanger

Operation platform

4 pieces 10BBL fermentation tanks

Glycol water tank

Chiller

Cooling pipes and valves

CIP unit

Control cabinet with semi automatic control system

This complete 10BBL beer equipment cost is around 75,000$-200,000$,there also also some factors affect the 10BBL beer equipment cost such as the valves and pipes which need to be designed as per your brewing requirements and brewery site floor plan,the steam boiler price and other special requirements from you.

The 10bbl brewhouse combination type.There are 10BBL 2-vessel brewhouse,10BBL 3-vessel brewhouse,10BBL 4-vessel brewhouse,10BBL 5-vessel brewhouse…each type of the brewhouse price has big difference

The 10bbl fermenter quantity you need.As we all the know,the more you need,the more you need to pay.If you don’t have enough money to buy the full quantity of the fermenters,we suggest you buy a couple of them at the first stage,when your brewery growing up,you can add them in the future.

Get in touch

Turnkey Solutions for your Brewing Process

Head office

Huixin Times Center, No. 2228 Tianchen Road, Jinan, China

Email us

Telephone

+86 531 86418866

+86 18006415555

Contact information

Speak with a sales representative during normal business hours (Monday – Friday, 8:30am – 5:30pm UTC+8).