Why choose Hgmc to supply your distillery equipment?

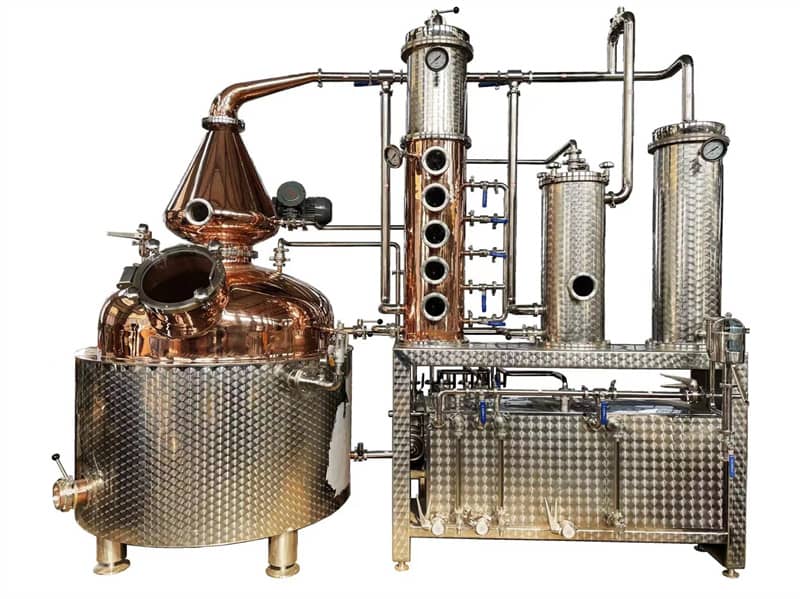

Hgmc presents an array of distilling equipment options, suitable for virtually any distilling operation. Our distilling equipment line includes a range of pot stills and continuous distillation stills along with supporting heating and cooling systems, fermentation and mashing equipment and all your related distillery needs.

1. Turnkey Solution Supply

Whether your craft distillery equipment budget is $5,000 or $500,000, we can provide you with a turnkey distillery solution, including mashing, fermentation, distillation, blending and storage, as well as ancillary machines, providing your distillery with a cost-effective solution with minimal maintenance costs.

2. High-Quality Materials

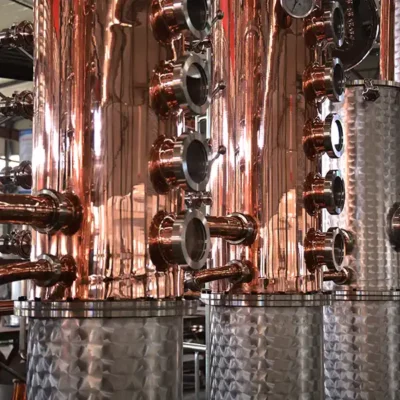

Our distillery equipment is constructed from high quality TP2 red copper materials, and food-grade stainless, ensuring long-term durability, corrosion resistance, and safety for your beverages.

3. Customized Proposal

Whether you need full set of distillation plant from A to Z, or only a distiller, from different production capacity, brewing characteristics, budget and space, Hgmc project managers and engineers will provide suitable solution. HGMC sales person is very experienced and understands clearly about different spirits making process, whiskey, gin, vodka,rum, brandy,etc.,

4. Strict Quality Control

Every part of our distilling equipment undergoes precision testing, from welding to polishing, ensuring that every tank meets the highest hygiene standards and supports smooth Clean-In-Place (CIP) cleaning processes. The quick-installation and copper welding methods ensure that the parts in contact with the alcohol are made of copper, with strong sealing performance and long service life.

Best distillery equipment manufacturer

Hgmc is a professional manufacturer of distillery equipment, and our mission is to provide distilleries and enthusiasts around the world with the absolute highest quality distillery equipment on the market today. We can handle all aspects of brewery construction from design to manufacturing to installation and training, so you can focus more on brewing technology. Additionally, we will dimension and install your boiler and cooling system.

PARAMETERS

| AVERAGE LOAD CAPACITY | AVERAGE CYCLE TIME | AVERAGE ENERGY CONSUMPTION | AVERAGE STEAM CONSUMPTION | ||

| Liters | Gallons | Hours | Hp/h | Kg/s | Lbs/h |

| 5000 | 1315 | 9 | 4.0 | 625 | 1377.9 |

| 4000 | 1052 | 8 | 3.0 | 500 | 1102.3 |

| 3000 | 789 | 7 | 2.0 | 375 | 826.7 |

| 2500 | 658 | 6.5 | 2.0 | 313 | 690.0 |

| 2000 | 526 | 6 | 1.5 | 250 | 551.1 |

| 1500 | 395 | 5.5 | 1.5 | 180 | 396.8 |

| 1200 | 317 | 4.5 | 1.0 | 140 | 308.6 |

| 1000 | 263 | 4.5 | 1.0 | 120 | 264.5 |

| 700 | 184 | 4 | 1.0 | 90 | 198.4 |

| 500 | 131 | 3.5 | 1.0 | 60 | 132.2 |

| 300 | 78 | 3 | 0.7 | 40 | 88.1 |

| 200 | 52 | 2.5 | 0.7 | 30 | 66.1 |

Distillation Equipment Configurations:

- Inner tank: TP2 copper/stainless steel, thickness 3mm/4mm/5mm/6mm depending on capacity of still pot

- Heating method: Interlayer steam heating or electric heating optional

- Available size: From 50L-5000L per batch

- With or without a stirring motor

- Tower column: 4-6 layers column plates with sightglass

- Suitable for whisky, gin, rum, fruit brandy, wine spirits

- Whiskey copper head

- Stainless steel condenser

- Stainless steel gold blue

- Stainless steel collection tanks

- Stainless steel support frame

- CIP cleaning pump

Other specifications based on the different sizes and type of alcohol to make:

- The first column: 4 sight glasses and 4 layers of trays, with liquid level lever

- Second column: 8 sight glass 8-layer trays with liquid level lever

- The third column: 8 sight glasses 8 columns, with liquid level lever

- Stainless Steel spirit storage tanks in sizes ranging from 50L-5000L

- Gin basket optional

Brewery Application Case

Frequently Questions

If you’re serious about your dreams, you’re going to need some basic equipment. When we say basic, we mean it, which is pretty much the bare minimum. So depending on what you want to extract, how much you want to produce, and what your process requires, you may need to adjust this list.

Source of water: Alcohol cannot be made without water. Distillation is essentially a process of adding and subtracting it throughout the production process, so you need a good source of water for your still. You can use limestone-rich water from streams or aquifers.

Heating unit: A heating unit is something you put the grain in with some H2O to heat everything to a certain temperature for a specified amount of time. It helps to install some piping in the cooker and send the cooked mixture to the fermenter, but the pump will suffice.

Fermentation tank: A fermentation tank is a large vessel in which you ferment grains, yeast, and water slurry. Yeast consumes sugar and produces alcohol in the process. After a few days (depending on your process) you will run the rest through the still.

Distilling equipment: This should go without saying, but to be more thorough, you will need a still to make drinkable alcohol. Also, it probably doesn’t hurt to install a drain on your floor to dispose of waste.

Hgmc will provide distilling Equipment service , design in 3D plant and CAD drawing .Hgmc salesperson is very experienced and understands clearly about different country distilling methods.

Hgmc provide installation and debugging service.

Hgmc technician will train the brewer to produce qualified craft spirit.

If the customer does not need our technician’s installation, we will also provide the installation diagrams, instructions to help them install by themselves.

Not at all. While there’s a huge boom right now, that’s not to say there isn’t more room to grow. Look at the craft breweries, new breweries are opening every week and the numbers are growing, as are craft spirits.

Most newly opened commercial breweries will set the size of the brewhouse to 10-30 barrels (1 barrel = 31.5 gallons = 2 big kegs = 240 pints of beer) and have fermentation tanks and bright tanks of the same size.

For new breweries whose sales and growth cannot be determined, adjusting the size of the brewery is a balance. In the beginning, using a relatively large brewhouse will put pressure on the initial expenditure, and using a smaller system will make it difficult to meet the demand and increase the cost of each batch of raw materials. You need to combine your brewing process and business growth to estimate the size of your brewhouse.

Considering the available space in the brewery, if there is not much space to add more fermentation tanks and bright tanks in the future, it is unwise to start with a large brewing system. You also need to combine the available space in the brewery and local regulations to determine the size of the brewhouse.

Starting a brewery is definitely all about making your own brewery a success and serving more people with delicious craft beer. But what should be done to be successful? You can refer to the following suggestions:

Base yourself on a niche market

Arm yourself with a solid brewery business plan

Know your budget and costs

Find a strong partner

Embrace new brewing techniques

Expect growth, don’t overextend

Maintain consistent quality

Take care of your business

You can fill out the contact form on our official website or directly reach out to our sales team for more information or a quote. We will provide detailed technical specifications and a quotation based on your needs.

Get in touch

Turnkey Solutions for your Brewing Process

Head office

Huixin Times Center, No. 2228 Tianchen Road, Jinan, China

Email us

Telephone

+86 531 86418866

+86 18006415555

Contact information

Speak with a sales representative during normal business hours (Monday – Friday, 8:30am – 5:30pm UTC+8).