Complete Brewery Solutions

Elevate your brewery with cutting-edge brewing technology, meticulously manufactured and backed by @HGMC. Your success is our priority.

Creating complete turnkey breweries is our specialty, and our satisfied customers can attest to our expertise and dedication.

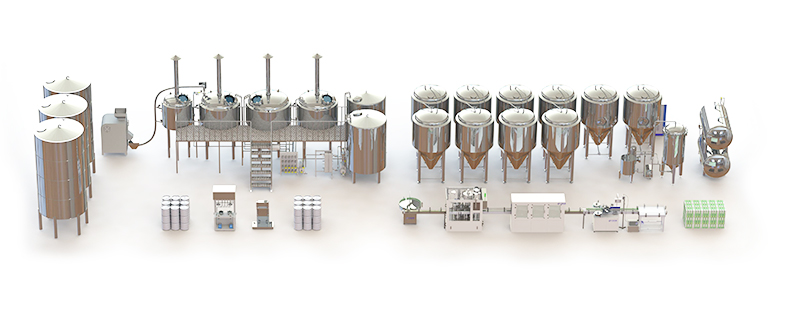

We provide a complete set of beer production equipment, including malting, mashing, fermentation, filling, sterilization, labeling, and packaging. With capacities ranging from 100L to 200T, it can meet the needs of small commercial breweries as well as large industrial breweries. Our equipment is efficient and energy-saving, which makes your production process simple and controllable, can produce any type of beer, and help you quickly occupy the market.

From design to installation, we are with you every step of the way. @HGMC is specializes in building brewery/distillery/winery in turrnkey solutions to your unique challenges.

The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Hgmc produced a variety of sizes and specifications of fermentation tanks. Customers can choose the most suitable fermentation tank according to their needs. As there are many types of beverages that need to be fermented, there are also many types of fermenters. Currently, Hgmc has a lot of experience in the production of beer, wine, cider fermentation vessel, our engineers can also customize the design of fermenters according to your requirements.

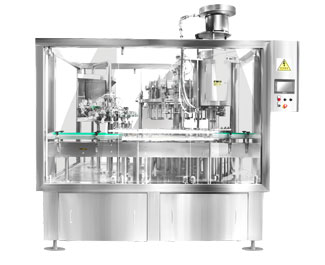

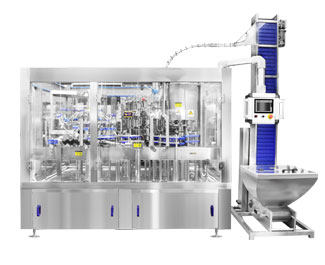

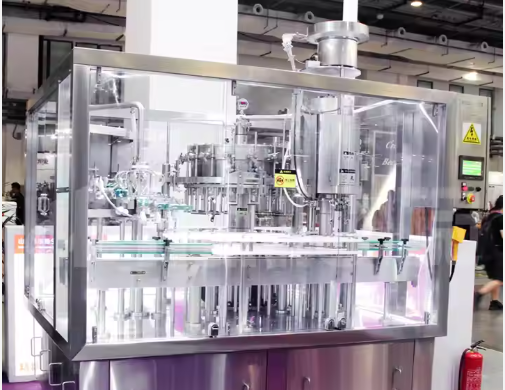

As well as filling a wide range of all beer types, such as lagers, ales, stouts, unfiltered wheat beers and bottle conditioned beers. Hgmc beer fillers can also be used for filling cider, hard cider, sparkling wines as well as carbonated soft drinks.

We also provide Malting Machine,Distillery Equipment,Kegging Machine ,BeerTunnel Pasteurizer and Other Beer Equipmen.

An equipment manufacture who knows beer best.

Shandong HG Engineering Equipment Co., Ltd. is the world’s leading manufacturer of beer brewing equipment. We produce brewery equipment, beverage equipment and canning/bottling lines. We have more than 30 national authorized patents and more than 20 high-tech achievements. We provide a full range of services, including individual equipment and turnkey projects. All products are in compliance with the ISO9001: 2015 quality management system, exported to more than 120 countries in the world, and have won recognition and praise from customers.

Feedback from our Netherlands customers

Feedback from our Greece customers

Feedback from our Croatia customers

Before you start procuring equipment, you need to have a clear cut of what you want to achieve with your brewing plant.

What types of beer will I be producing?

What’s my anticipated production capacity per week?

Which brewing process am I adopting?

Which Brewery System is right for me?

Having answered these questions, click to view our brewery solutions.

These include grain silos, mills, weighing systems, mash tuns, pumps, lauter tuns, wort grants, coolers and aerators, brew kettles, yeast handling systems, fermenters, bright beer tanks, filters, and a variety of other tanks for mixing and storage..

For this first brew you’ll need:

As for our quality, all our raw materials used are stainless steel 304 or 316 material, the plate is all perfect 3mm and 2mm, some manufacturers with low prices, but they are 2.7mm.

Our factory have strict quality control and process inspection & testing system to make sure you get the quality you expect and delivery on time. Each of our orders shipment will have 5 inspection steps and the inspection record from materials in checking, production process, jacket pressure testing by water and air, finished product inspection and 48 hours water testing, equipment packing and loading inspection, finished product to the delivery and packing process, etc. Every of our tank will have the data plate with the pressure testing record and serial numbers to track. Testing 12hours with air and water, jacket testing pressure is 5Bar, internal shell testing pressure is 4Bar, and before packing we will also have 48hours water testing, which all these testing record will show on our data late with the tanks shipping.

Also for packing and shipping, we also have our strict standards, the shipping department will work out the checking list and pack them in wooden box, you will receive a checking list with everything we shipped.

The 10-barrel brewing system is equipped with heating methods, including electric, steam, and gas heating. HGMC also offers a variety of turnkey control methods.

The cost of a 10 BBL brewhouse chamber may vary depending on the function and specification of the glycosylation chamber. A basic, entry-level 10 BBL brewhouse chamber costs about $75,000, while more advanced high-end models can cost as much as $200,000.

Some factors that affect the cost of a 10BBL brewhouse chamber include the type of brewhouse chamber (e.g. electric, gas, or steam combustion), the type of brewing process (e.g. batch or continuous), the level of automation, and the type of finishing equipment (malting plant, granary, wort cooler, etc.).

Normally our production circle is from 30-50working days depending on the order.

For the time being, from the day we get your deposit to the delivery we are looking at 90-150 days at your door delivery. Our leadtime will vary depending on our factory workload but we do like to keep honest leadtimes so there is no surprises except getting the equipment earlier that what it was suppose to.

es, we support product customization.

We are a factory, so you can tell our sales manager about the product requirements, and our engineers will design your own drawings for you.

We are manufacture of brewhouse in 2 vessel, 3 vessel and 4 vessel configurations and provide commercial brewery from 1HL to 500HL sizes for a wide range brewery needs.

This is not a question that can be answered very accurately, because every brewery has different requirements. If your brewery is too small, your space will be crowded. If your space is too large, you will waste a lot of money on startup costs and the space will not be well utilized. But we can provide you with some tips: 3BBL~5BBL brewery equipment needs about 300~500 square feet, and 7BBL~15BBL brewery equipment needs about 550~1200 square feet. Of course, if you need relatively accurate numbers, welcome to leave us a message.

Let’s take a common designed 10BBL beer equipment system as example,the list of the brewing system as below:

10BBL Mash/lauter tun

10BBL Kettle/Whirlpool tun steam heated

20BBL Hot water tank

3m3 wort pump and hot water pump

Stainless steel 304 wort pipes

10m2 plate heat exchanger

Operation platform

4 pieces 10BBL fermentation tanks

Glycol water tank

Chiller

Cooling pipes and valves

CIP unit

Control cabinet with semi automatic control system

This complete 10BBL beer equipment cost is around 75,000$-200,000$,there also also some factors affect the 10BBL beer equipment cost such as the valves and pipes which need to be designed as per your brewing requirements and brewery site floor plan,the steam boiler price and other special requirements from you.

The 10bbl brewhouse combination type.There are 10BBL 2-vessel brewhouse,10BBL 3-vessel brewhouse,10BBL 4-vessel brewhouse,10BBL 5-vessel brewhouse…each type of the brewhouse price has big difference

The 10bbl fermenter quantity you need.As we all the know,the more you need,the more you need to pay.If you don’t have enough money to buy the full quantity of the fermenters,we suggest you buy a couple of them at the first stage,when your brewery growing up,you can add them in the future.

Turnkey Solutions for your Brewing Process

Huixin Times Center, No. 2228 Tianchen Road, Jinan, China

+86 531 86418866

+86 18006415555

Speak with a sales representative during normal business hours (Monday – Friday, 8:30am – 5:30pm UTC+8).