What is Yeast Propagation?

Yeast propagation is the process of growing and multiplying yeast cells. Yeast cells are single-celled organisms that are responsible for converting sugar into alcohol during fermentation. Yeast propagation is important because it allows brewers to create and maintain healthy yeast populations, which are essential for consistent beer quality.

Why is Yeast Propagation Important in Brewing?

Yeast is the most important ingredient in beer, and the health and vitality of yeast cells directly affect the quality of the final product. A healthy yeast population is necessary for consistent fermentation, which is essential for creating a beer that is free from off-flavors and aromas. Yeast propagation is also important because it allows brewers to maintain consistency in their beer recipes by using the same strain of yeast in each batch.

When producing craft beer, yeast expansion can be carried out in the following steps:

1. Preparation stage:

Under a sterile environment, take out the yeast strain from the inclined test tube, or activate the dry yeast powder as the original strain.

2. Laboratory expansion culture

– Inoculate the yeast into a test tube containing 5ml of wort, place it at about 25℃ for 48 hours, and shake it gently 3 times a day.

– Transfer it to a triangular flask containing 50ml of sterile wort, place it at room temperature for 24 hours, and shake it 3 times a day.

– Transfer it to 500ml of sterile wort and place it at room temperature for 24 hours. At this stage, pay attention to shaking the container regularly every day to achieve the purpose of oxygen supply.

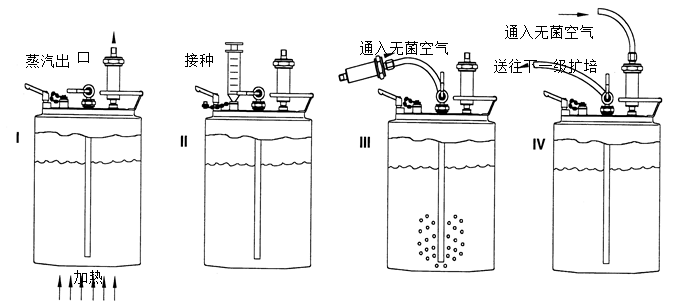

3. Production site expansion culture

– Transfer the yeast solution to a larger container, such as a 1-liter Karl jar, aluminum barrel, yeast breeding tank, etc.

– Regularly introduce sterile compressed air for oxygen supply.

– Each time the culture is expanded, the seed liquid in the late logarithmic growth period is used for inoculation. Generally, the logarithmic growth period is when the foam reaches the highest point and is about to fall back.

– Control the temperature. The optimal growth temperature of yeast is 25℃ at the beginning of the culture. After each expansion, the temperature is lowered to make the yeast gradually adapt to the requirements of low-temperature fermentation.

4. Repeat the culture: Repeat the above steps until the number of yeast reaches the required number.

At the same time, the following points should be noted for yeast expansion:

Environment and equipment sterility: The laboratory should be sterilized regularly, and the indoor air should be thoroughly sterilized the day before inoculation, and then sterilized again before inoculation. Experimental instruments such as test tubes and triangular flasks should be sterilized at 0.1Mpa for about 30 minutes.

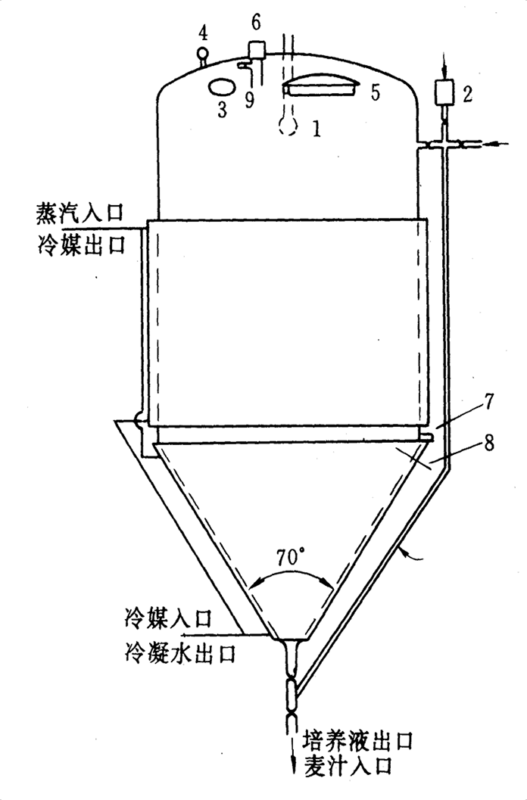

Good wort composition: The wort concentration should be controlled at 10-12p and sterilized before use. The laboratory sterilization time is 0.1Mpa, about 30 minutes, and the workshop expansion wort is heated to 100 degrees in the Hansen tank and the expansion tank for 30 minutes for sterilization. The nutrition of the expansion wort should be sufficient, the content of free amino nitrogen should be controlled at about 200mg/l, the zinc ion content should be greater than 0.15mg/L, and yeast nutrient salts can be added in appropriate amounts.

Reasonable timing and multiples of additional addition: the ratio of yeast expansion should be reasonable, generally 10-20 times in the laboratory stage and 4-5 times in the production site. The growth process of yeast is divided into a retardation period, a logarithmic growth period, a saturation period and an aging and death period. Transplanting in the logarithmic growth period for 2-3 hours has a high germination rate, the lowest mortality rate, the shortest retardation time, and the most vigorous value-added. It is generally recommended that the yeast concentration be transferred at about 60 million/ml or the transfer time be controlled by sugar content.

Control the transfer temperature difference: The expansion temperature should be stable to avoid large fluctuations. It is best to control the temperature difference at about 3 degrees during the transfer. Too large a temperature difference will cause the yeast cells to be cold-shocked, resulting in the yeast not being able to ferment normally in the later stage.

Control the dissolved oxygen: There are many ways to oxygenate in the laboratory stage, and the best way is an oscillator. Intermittent or continuous oxygenation can be used at the production site, and the dissolved oxygen is controlled at 8-10mg/L to avoid yeast fermentation to produce alcohol.

Control the pH value of wort: The pH value of wort should be controlled between 5.2-5.6.5

Conclusion

Yeast propagation is a critical component of the brewing process, as it allows brewers to maintain healthy yeast populations and produce consistent, high-quality beer. There are several different types of yeast propagation systems available, each with its own advantages and disadvantages. By following best practices for yeast propagation, brewers can ensure that their yeast populations remain healthy and viable, leading to a more consistent and enjoyable final product.