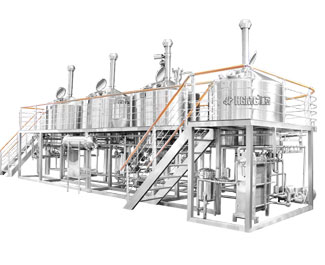

Capacity More Than 1000L -3000L

Micro brewery equipment is well-suited for craft brewers who want to produce high-quality, small-batch beers with precision and creativity. Whether you’re a homebrewer looking to scale up your operation or a professional brewer starting a small brewery, microbrewery equipment provides the tools and flexibility needed to produce unique and delicious craft beers.When determining your investment costs, we offer a range of equipment options and financing solutions tailored to brewery needs, ensuring a smooth startup and operational launch.

One-stop service from an idea to a finished micro brewery

Hgmc proffessinal team will provide you with a detailed brewery layout and includes all heating, refrigeration, pumps, valves, pipe-work and controlsWe offer steam-powered, direct fire, and electric brewhouses in 2, 3, 4, and 5 – vessel configurations. If you’ve never started a brewery before, we’re here to help. If you’re an experienced brewer, we speak your language.

Capacity:

Volume of wort per batch 1000L – 3000L

Site Requirements and Recommendations:

- Height Specifications: Micro Craft Brewery Equipment (10 HL – 30 HL) and require a ceiling height of 12.5ft. (custom heights available)

- Drainage: 4″ inch floor drain is preferred;

- Electrical: 3 phase/380(220, 415,480…)v/50(60)Hz; Single Phase/220(110, 240…)v/50(60)Hz

- Control Level: Control PID display control panel, PLC semi-automatic touch screen panel, PLC fully automatic control panel

- Heating Method: Electric/steam/direct fire heating

- Welding: TIG 100% full welding joints

- Polishing Accuracy: ≤0.4μm

- Heat Transfer Efficiency: ≥90%

Micro Craft Brewery System Features

Advantages and Limitations of Micro Craft Brewing

Benefits and Opportunities with Micro Craft Breweries

Freedom for brewers to experiment with recipes and ingredients

Focus on flavor, aroma, and appearance

Engage customers with speciality offerings and seasonal varieties

Build loyal local following and brand identity

Charge premium price points for perceived quality

Lower startup capital investment requirements

Owner operated maintains flexibility and control

Capability to grow production incrementally avoids large debt

Potential Weaknesses and Risks Facing Small Breweries

Consistency batch to batch can be challenging

Floorspace limitations may constrain growth

Stainless equipment has high upfront costs

Securing bank loans difficult without proven financials

Must price competitively as market saturates

Expensive Federal and State licensing fees

Staffing challenges finding qualified brewers

Distribution without discounts tough for retailers

High failure rate as fads change in craft beer

Additional Usage Spaces:

1000L/2000L Parameter

| Model | HG-1000 / 1000L 3 Vessel Beer Brewing Equipment | HG-1000 / 1000L 4 Vessel Beer Brewing Equipment | HG-1000 / 1000L 2 Vessel Beer Brewing Equipment | HG-1000 /2000L 2 Vessel Copper Beer Brewing Equipment | HG-2000 / 2000L 3 Vessel Beer Brewing Equipment |

| Capacity | 1000L/Batch | 1000L/Batch | 1000L/Batch | 1000L/Batch | 2500L/Batch |

| Material | Stainless steel | Stainless steel | SUS304 | Copper | SUS304 |

| Combination method | Mash/Kettle tank, Lauter and whirlpool connection tank | Mash/Kettle tank, Lauter and whirlpool connection tank | Mash/Kettle tank, Lauter and whirlpool connection tank | Mash/Kettle tank, Lauter and whirlpool connection tank | Mash tun, Lauter tun, Kettle/whirlpool tank |

| Application | Restaurants, bars, hotels, brewery | Restaurants, bars, hotels, brewery | Restaurants, bars, hotels, brewery | Restaurants, bars, hotels, brewery | Restaurants, bars, hotels, brewery |

| Heating way | Steam heating/Electric heating/Direct fire heating | Steam heating/Electric heating/Direct fire heating | Steam heating/Electric heating/Direct fire heating | Steam heating/Electric heating/Direct fire heating | Electric heating/Steam heating/Direct fire heating |

| Voltage | AC380/220V, 50/60HZ | AC380/220V, 50/60HZ | AC380/220V, 50/60HZ | AC380/220V, 50/60HZ | AC380/220V, 50/60HZ |

| Power | 15kw | 15kw | 15kw | 15kw | Electric heating:144kw, Steam heaing/Direct fire heating 55KW |

| Water consumption | 4m3/T | 4m3/T | 4m3/T | 4m3/T | 4m3/T |

| Diameter | 1560mm | 1560mm | 1560mm | 1560mm | 1960mm |

| Height | 3000mm | 3000mm | 3000mm | 3000mm | 3200m |

| Floor area | 10m2 | 10m2 | 10m2 | 10m2 | 60m2 |

| Degree of automation | Semi-automatic/Fully automatic | Semi-automatic/Fully automatic | Semi-automatic/Fully automatic | Semi-automatic/Fully automatic | Semi-automatic/Fully automatic |

Brewery Application Case

Frequently Questions

The Brewers Association defines micro craft breweries as producing under 15,000 barrels per year. That equates to brewing no more than 450,000 US gallons annually.

Before you start procuring equipment, you need to have a clear cut of what you want to achieve with your brewing plant.

What types of beer will I be producing?

What’s my anticipated production capacity per week?

Which brewing process am I adopting?

Which Brewery System is right for me?

Having answered these questions, click to view our brewery solutions.

Used equipment saves substantially on upfront capital costs. But results vary greatly depending on age, maintenance performed, upgrades needed for controls and reconditioning, and warranty support. Evaluate operational expenses over lifetime of tanks.

For this first brew you’ll need:

- A beer kit.

- A fermenting bucket.

- An airlock.

- A tap or siphon.

- A bottle stick.

- A long stirrer.

- Caps and a capper and some means to clean and sanitise your equipment.

As for our quality, all our raw materials used are stainless steel 304 or 316 material, the plate is all perfect 3mm and 2mm, some manufacturers with low prices, but they are 2.7mm.

Our factory have strict quality control and process inspection & testing system to make sure you get the quality you expect and delivery on time. Each of our orders shipment will have 5 inspection steps and the inspection record from materials in checking, production process, jacket pressure testing by water and air, finished product inspection and 48 hours water testing, equipment packing and loading inspection, finished product to the delivery and packing process, etc. Every of our tank will have the data plate with the pressure testing record and serial numbers to track. Testing 12hours with air and water, jacket testing pressure is 5Bar, internal shell testing pressure is 4Bar, and before packing we will also have 48hours water testing, which all these testing record will show on our data late with the tanks shipping.

Also for packing and shipping, we also have our strict standards, the shipping department will work out the checking list and pack them in wooden box, you will receive a checking list with everything we shipped.

Plan for at least 1,500-3,000 sq ft for a small 3-7 BBL micro brewery. This includes the brewhouse plus fermentation room, cold storage, packaging area, ingredients, lab, and offices. More space allows more comfortable production volumes and future growth capacity.

- Sales & engineers could be keeping 24 hours online for service.

- HGMC provides a 6 year warranty on tanks sold with manufacturing defects from the factory.

- HGMC provides a 6 year warranty on tank accessories&electronic components provided they are used under the scope.

- HGMC does not cover damage to tanks from unloading of tanks at customer site, damage resulting from improper use of tanks for products other than beer or appropriate beverage, damage from exceeding designed tanks pressure, damage from CIP or cleaning, usage above and beyond the scope of the tanks design.

Normally our production circle is from 30-50working days depending on the order.

For the time being, from the day we get your deposit to the delivery we are looking at 90-150 days at your door delivery. Our leadtime will vary depending on our factory workload but we do like to keep honest leadtimes so there is no surprises except getting the equipment earlier that what it was suppose to.

es, we support product customization.

We are a factory, so you can tell our sales manager about the product requirements, and our engineers will design your own drawings for you.

We are manufacture of brewhouse in 2 vessel, 3 vessel and 4 vessel configurations and provide commercial brewery from 1HL to 500HL sizes for a wide range brewery needs.

This is not a question that can be answered very accurately, because every brewery has different requirements. If your brewery is too small, your space will be crowded. If your space is too large, you will waste a lot of money on startup costs and the space will not be well utilized. But we can provide you with some tips: 3BBL~5BBL brewery equipment needs about 300~500 square feet, and 7BBL~15BBL brewery equipment needs about 550~1200 square feet. Of course, if you need relatively accurate numbers, welcome to leave us a message.

Key utilities are electricity, water, drainage, ventilation, refrigeration, gas lines for any direct-fired kettles, and steam if applicable. Ensure adequate connection sizes, pressure, drainage slope, and phased electrical distribution.

Get in touch

Turnkey Solutions for your Brewing Process

Head office

Huixin Times Center, No. 2228 Tianchen Road, Jinan, China

Email us

Telephone

+86 531 86418866

+86 18006415555

Contact information

Speak with a sales representative during normal business hours (Monday – Friday, 8:30am – 5:30pm UTC+8).