Beer brewing has transformed from a centuries-old craft into a modern science that blends tradition, creativity, and technology. Central to this transformation is the equipment used in brewing, which has evolved to meet the needs of hobbyists and commercial brewers alike. Whether brewing at home or operating a large-scale brewery, having the right equipment is essential for producing consistent and high-quality beer. The brewing process involves several stages, each requiring specialized tools and vessels to handle everything from mashing to fermentation. With the growing interest in craft beer, more people are investing in brewing setups tailored to their taste and production goals. Understanding the role of each piece of equipment helps brewers refine their methods and improve the final product. From basic kits to advanced systems, beer brewing equipment is the foundation of a successful brew.

At the heart of any brewing setup is the brew kettle, a large pot used to boil water and wort—the liquid extracted from malted grains. Brew kettles come in various sizes, materials, and configurations, but stainless steel is the most preferred due to its durability and resistance to corrosion. Some advanced kettles feature built-in thermometers, volume markers, and spigots to improve precision and ease during brewing. The size of the kettle depends on the batch size, with home brewers typically using five to ten-gallon kettles, while microbreweries might require much larger versions. Proper temperature control during the boil is crucial to extracting the right flavors and eliminating unwanted compounds. The brew kettle also plays a role in hop addition, where the timing and amount can greatly influence the beer’s aroma and bitterness. A well-designed kettle makes it easier to manage these factors and streamline the brewing process.

Next comes the mash tun, which is used to steep crushed grains in hot water during the mashing phase. This process allows enzymes in the malt to break down starches into fermentable sugars, forming the wort. Mash tuns can be as simple as a converted cooler or as complex as insulated vessels with false bottoms and sparging arms. Insulation is important in maintaining a stable temperature throughout the mashing process, which typically lasts about an hour. Sparging follows mashing, where hot water is rinsed through the grain bed to extract remaining sugars. The wort is then collected and transferred to the brew kettle for boiling. Choosing the right mash tun design depends on the brewer’s volume requirements and desired level of control over the mash process. The more control a brewer has, the more consistent the outcome across different batches.

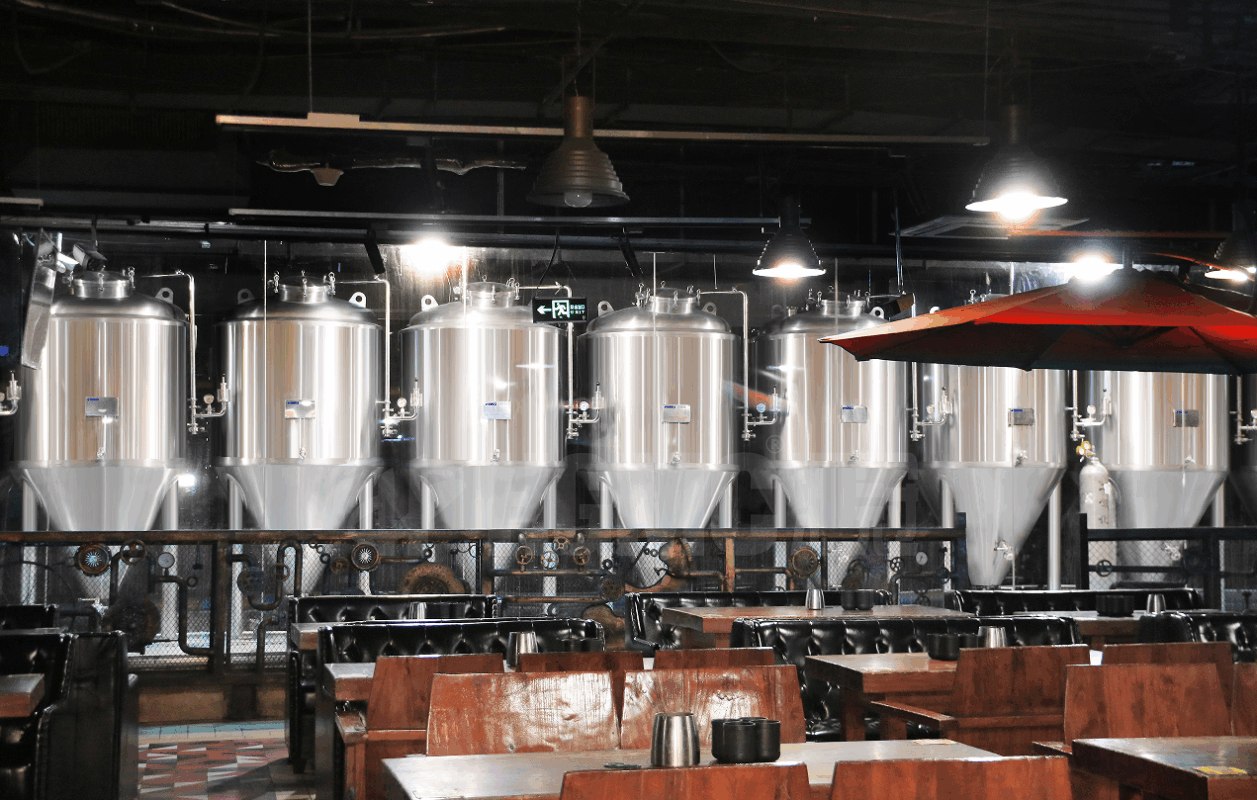

Once the wort is boiled and cooled, it must be transferred to a fermentation vessel where yeast is added. Fermenters are available in plastic, glass, and stainless steel, with each material offering its own advantages. Glass fermenters are easy to clean and allow brewers to monitor the fermentation visually, but they are fragile. Plastic fermenters are lightweight and affordable, though they may be prone to scratches and odors over time. Stainless steel fermenters, on the other hand, are highly durable, easy to sanitize, and often come with valves and ports for sampling and racking. Temperature control during fermentation is essential for developing the beer’s flavor profile, as different yeast strains require specific temperature ranges. Advanced setups may include fermentation chambers or glycol chillers to maintain optimal conditions. A good fermenter not only stores the beer but also supports a clean and efficient fermentation process.

Sanitation is a vital aspect of beer brewing, and proper cleaning equipment ensures that no unwanted bacteria or wild yeast contaminate the brew. Everything that touches the beer after the boil must be thoroughly sanitized, from fermentation vessels to tubing and bottling tools. Many brewers use specialized sanitizing agents that are no-rinse and safe for brewing equipment. Brushes, spray bottles, and cleaning solutions are part of a typical cleaning kit. Neglecting cleanliness can result in off-flavors or even ruined batches, which is why many seasoned brewers consider sanitation as important as the brewing process itself. Some advanced setups include Clean-In-Place (CIP) systems that automate the sanitation of brewing vessels. Whether brewing on a small or large scale, maintaining high sanitation standards is key to producing great-tasting beer.

Finally, packaging the beer marks the completion of the brewing cycle. Bottling or kegging equipment is necessary to store and carbonate the beer for consumption. Bottling involves siphoning the beer into sanitized bottles, adding priming sugar, and capping each bottle securely. This method is ideal for home brewers or small batches, and it allows for easy sharing and transport. Kegging, while requiring more upfront investment, is faster and provides better control over carbonation and dispensing. It uses CO2 tanks and regulators to pressurize the keg and push the beer through a tap system. Some brewers also use counter-pressure bottle fillers to bottle from kegs without losing carbonation. Regardless of the method, having reliable packaging equipment ensures the beer stays fresh and enjoyable from the first pour to the last sip.