What is a Beer Manufacturing Plant?

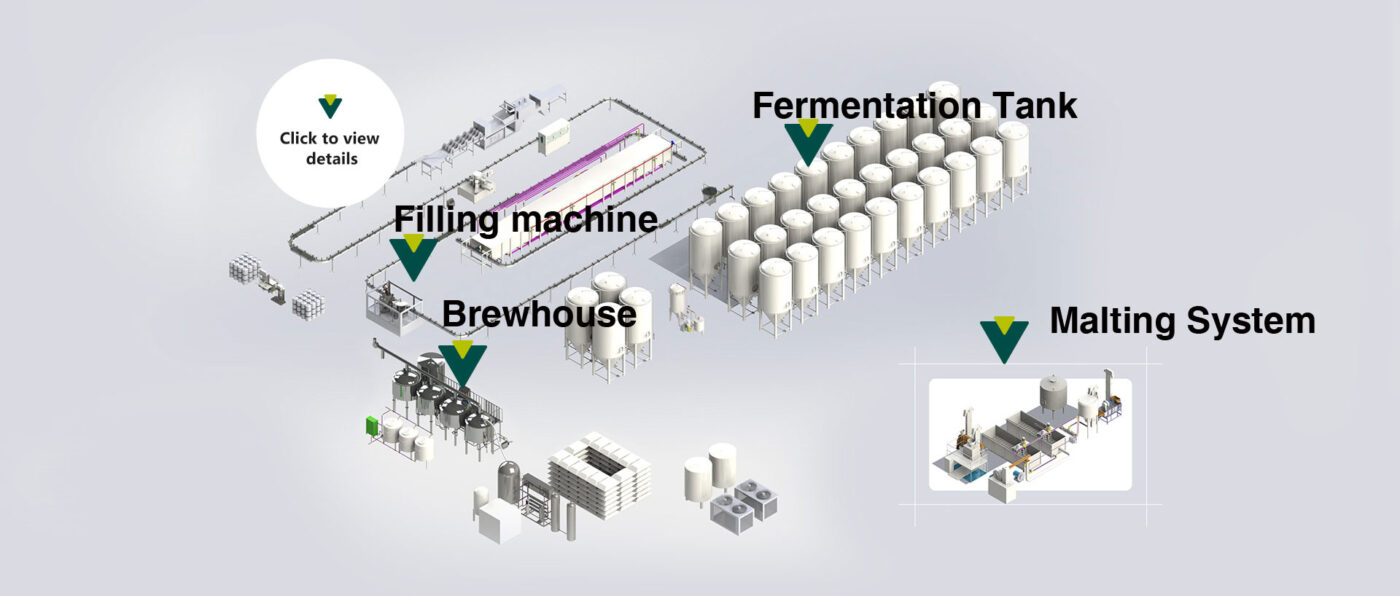

A beer manufacturing plant is a facility where raw materials like malt, hops, water, and yeast are transformed into beer through a series of brewing processes. These plants utilize specialized equipment for mashing, lautering, boiling, fermentation, maturation, and packaging, ensuring consistent quality and efficiency in beer production.

What makes a beer manufacturing plant truly fascinating is its blend of tradition and technology. While brewing techniques have ancient roots, today’s plants are often semi-automated or fully automated with smart control systems to ensure consistency and efficiency.

Beer Production Process in a Manufacturing Plant

The beer production process in a manufacturing plant is an intricate journey, full of chemistry, patience, and a little bit of magic. It can be broken down into several detailed stages:

Malting

First comes malting. Barley grains are soaked, germinated, and then dried in kilns. This step activates enzymes that are essential for breaking down starches into fermentable sugars. Compared to unmalted grains, malted barley offers richer flavors and higher sugar content, which is perfect for fermentation.

Mashing

Once malted, the barley is ground into grist and mixed with hot water in the mash tun. Here, enzymes go to work converting starches into sugars. Imagine brewing a giant pot of sweet oatmeal—that’s mashing. The result is a sugary liquid known as wort.

Lautering

Next, the wort is separated from the grain husks. The liquid is drained while the grain bed acts as a natural filter. The remaining wort is rich, sweet, and ready for the next stage.

Boiling

The wort is then boiled and hops are added. Hops bring bitterness that balances the sweetness and also contribute to the aroma. The type and timing of hops added can dramatically change the beer’s character. Compared to no-hop beers, hopped beers have longer shelf life and a more complex taste.

Fermentation

After boiling, the wort is cooled and transferred to fermentation tanks. Yeast is added, and fermentation begins. This is where sugars turn into alcohol and carbon dioxide. Different yeasts and fermentation temperatures yield different beer styles.

Maturation

Post-fermentation, the beer is allowed to mature. This can range from a few weeks to several months depending on the beer type. Lager, for example, requires longer maturation compared to ale.

Packaging

Finally, the beer is filtered, carbonated if necessary, and packaged into bottles, cans, or kegs. Some plants pasteurize the beer for longer shelf life, while others skip this step for craft or fresh beers.

Key Equipment in a Beer Plant

Choosing the right beer plant equipment is like picking the perfect tools for a master chef. Each piece plays a vital role and skipping or skimping on one can ruin the entire batch.

Mash Tun versus Brew Kettle

The mash tun is where sugars are extracted from the grains. It needs to maintain a steady temperature for enzymatic activity. On the other hand, the brew kettle must handle high heat during boiling and integrate hops efficiently. Both are essential but serve totally different purposes—one extracts sugars, the other shapes flavor.

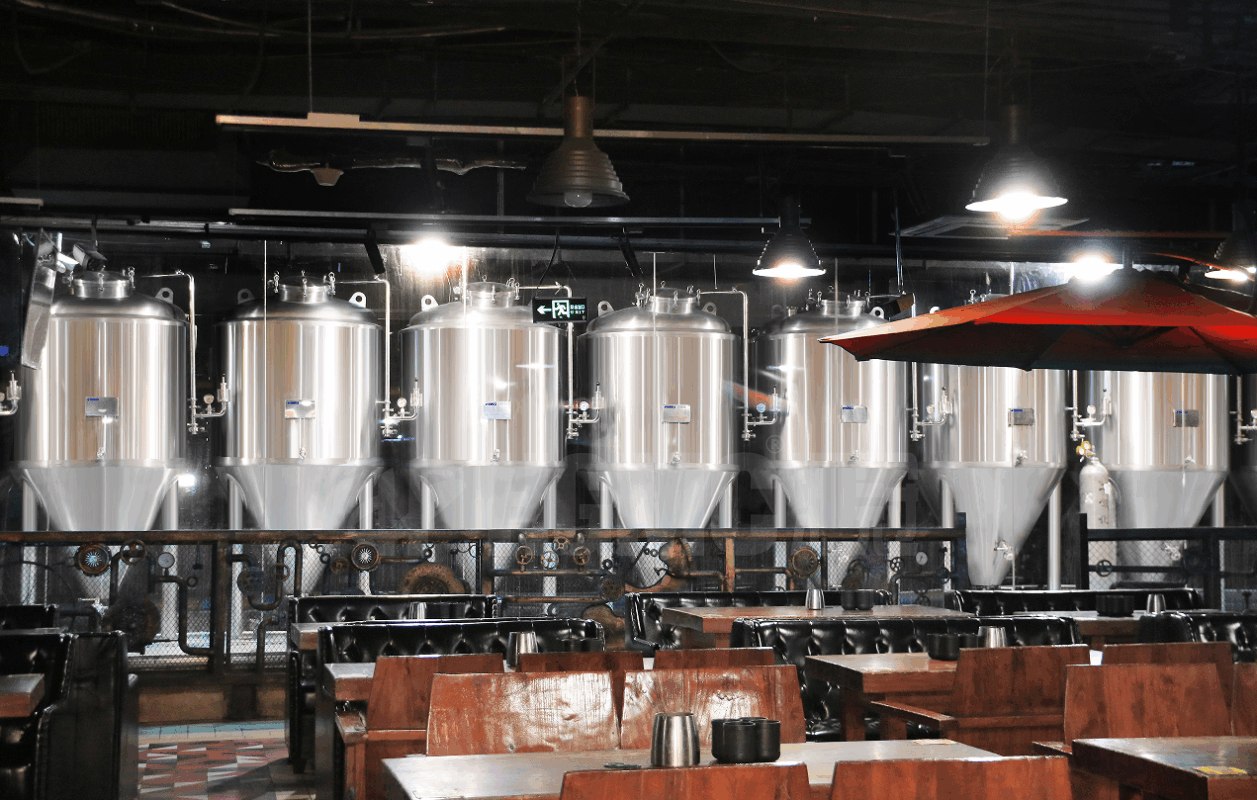

Fermentation Tanks: Size and Material

These tanks must withstand internal pressure and maintain specific temperatures. Stainless steel is better than plastic or glass for large operations because it resists corrosion and is easier to clean. Fermentation tanks range from small 50-liter units for microbreweries to gigantic 5000-liter vessels in large plants.

Filtration Systems: Clarity versus Cloudiness

A good filtration system ensures the beer is clear and free from unwanted particles. Some craft breweries deliberately skip intense filtration to keep the “cloudy” appeal of certain beers like Hefeweizens, but mass-produced beers aim for crystal-clear consistency.

How to Choose the Right Beer Plant Equipment Supplier

Picking a beer plant equipment supplier is like choosing a partner for a long journey. You need someone reliable, experienced, and aligned with your goals.

Quality versus Cost

Cheaper equipment might save money upfront but can lead to higher maintenance costs and production delays. European and American suppliers often have higher prices but also better build quality and support compared to some low-cost alternatives.

Customization Options

A good supplier offers customization to match your brewery size, beer type, and budget. They should also provide comprehensive manuals, training, and after-sales support.

Reputation and Reviews

Research supplier reputations through customer reviews, site visits, and industry forums. Suppliers with proven track records usually deliver on both quality and timelines.

Shandong HG Engineering Equipment Co., Ltd. is the world’s leading manufacturer of beer brewing equipment. Hgmc produce brewery equipment, beverage equipment and canning/bottling lines. We have more than 30 national authorized patents and more than 20 high-tech achievements. We provide a full range of services, including individual equipment and turnkey projects. All products are in compliance with the ISO9001: 2015 quality management system, exported to more than 120 countries in the world, and have won recognition and praise from customers.HGMC’s 23 years in modern brewing, 5,000+ built breweries, and a full range of services from design to after-sales support make it a reliable choice for brewers who want results without worry.

300L Beer Brewing Equipment

500L Beer Brewing Equipment

1000L Beer Brewing Equipment

2000L Beer Brewing Equipment