A comprehensive guide to automatic distillation systems for craft distilleries, industrial alcohol production, and beverage manufacturing facilities.

What is an Automatic Alcohol Distillation System?

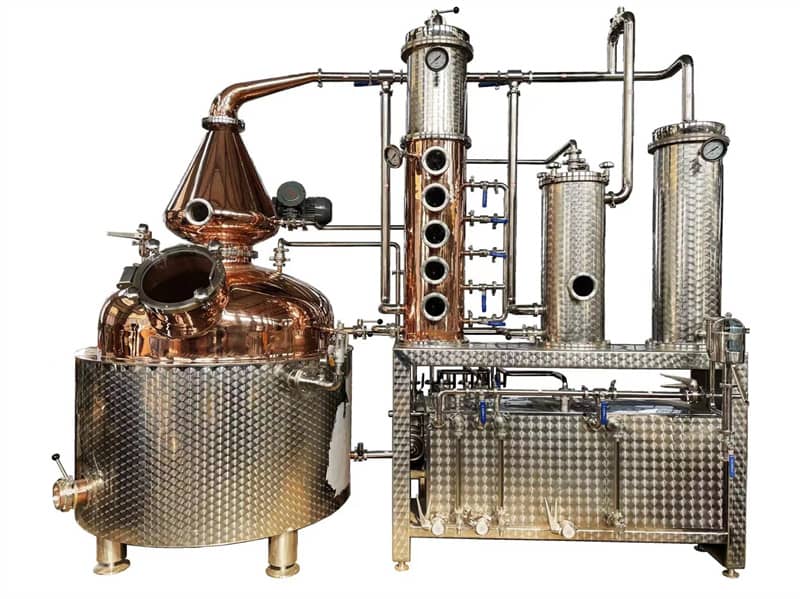

An automatic alcohol distillation system is a fully integrated industrial apparatus designed to separate alcohol from fermented liquids through controlled heating, vaporization, and condensation processes. Unlike traditional manual stills, automatic distillation units incorporate advanced sensors, programmable logic controllers (PLCs), and automated valves to maintain precise temperature control, reflux ratios, and cut points throughout the distillation cycle.

Modern automatic distillation systems consist of several key components:

- Boiler/Still Pot: The primary heating vessel where the fermented wash is heated

- Distillation Column: A vertical tower containing plates or packing material for vapor-liquid contact

- Condenser: Heat exchanger that cools alcohol vapors back into liquid form

- Control System: PLC or computer interface managing temperature, pressure, and flow rates

- CIP (Clean-in-Place) Systems: Automated cleaning circuits for sanitation

According to DISCUS (Distilled Spirits Council of the United States), the craft distilling industry has grown by 15.5% annually since 2010, with automated systems becoming increasingly essential for consistent quality and regulatory compliance.

Pot Still vs Column Still vs Automatic Distillation Unit — Which is the Right Alcohol Distillation Equipment?

Pot Still Systems

Pot stills represent the traditional method of distillation, particularly favored for whisky, brandy, and artisanal spirits production.

Advantages:

- Preserves complex flavor compounds and congeners

- Ideal for batch production of premium spirits

- Lower initial investment ($15,000-$150,000)

- Simpler maintenance requirements

Limitations:

- Labor-intensive operation requiring constant monitoring

- Lower alcohol yield (typically 60-70% ABV maximum)

- Longer production cycles (8-12 hours per batch)

- Inconsistent results without experienced operators

Column Still (Continuous Still)

Column stills utilize multiple distillation stages in a single vertical column, enabling continuous operation and higher purity alcohol production.

Advantages:

- Produces high-proof neutral spirits (95%+ ABV)

- Continuous operation increases throughput

- Energy-efficient compared to multiple pot still runs

- Consistent product quality

Limitations:

- Strips out flavor compounds (not ideal for character spirits)

- Higher capital investment ($50,000-$500,000+)

- More complex operation and maintenance

- Requires larger production volumes to justify costs

Automatic Distillation Units

Automatic distillation systems combine the best features of traditional stills with modern automation technology, suitable for both batch and continuous operations.

Advantages:

- Precise computer-controlled temperature and reflux management

- Reduced labor costs (up to 60% according to Brewing Industry Guide 2024)

- Consistent product quality batch-after-batch

- Real-time monitoring and data logging for compliance

- Programmable recipes for different spirit types

- Safety features including automatic shutdown protocols

Investment Range:

- Small-scale automatic systems: $75,000-$200,000

- Medium industrial units: $200,000-$800,000

- Large production facilities: $800,000-$3,000,000+

Selection Criteria Comparison Table

| Factor | Pot Still | Column Still | Automatic System |

|---|---|---|---|

| Production Volume | 50-500L/batch | 500-5000L/day | 100-10,000L/day |

| Alcohol Purity | 60-70% ABV | 95-96% ABV | 70-96% ABV (adjustable) |

| Flavor Retention | High | Low | Medium-High (programmable) |

| Labor Requirements | High | Medium | Low |

| Initial Cost | |||

| Operating Cost | High | Medium | Low |

| Consistency | Variable | High | Very High |

How Does an Automatic Distillation System Work? (Boiler, Vapor, Condenser, Control)

The automatic distillation process follows a precisely controlled thermodynamic cycle:

1. Boiler/Heating Phase

The boiler (or still pot) is filled with fermented wash containing 8-15% alcohol by volume. In automatic systems, the heating process is controlled by:

- Electric heating elements with PID (Proportional-Integral-Derivative) controllers

- Steam jackets for indirect heating in larger industrial units

- Thermal sensors (RTD or thermocouples) providing temperature feedback

Heating power typically ranges from 15-30 kW for craft systems to 500+ kW for industrial operations. The boiler gradually heats the wash to approximately 78-80°C (172-176°F), the boiling point of ethanol at atmospheric pressure.

2. Vaporization and Rectification

As the wash reaches optimal temperature:

- Alcohol and volatile compounds vaporize first due to lower boiling points

- Vapors rise through the distillation column containing bubble plates, perforated trays, or structured packing

- Counter-current contact with descending liquid (reflux) creates multiple distillation stages

- Automatic systems adjust reflux ratio (typically 3:1 to 10:1) via solenoid valves

According to Perry’s Chemical Engineers’ Handbook, each theoretical plate in a distillation column increases separation efficiency by 40-60%, with modern automatic columns containing 10-30 theoretical plates.

3. Condensation System

Alcohol vapors reaching the column top enter the condenser, where:

- Shell-and-tube or plate heat exchangers remove heat

- Cooling water (typically 10-20°C) flows counter-current to vapor

- Vapors condense into liquid distillate

- Cooling water flow rates are automatically adjusted to maintain 60-65°C condensation temperature

Cooling Requirements: For every liter of pure alcohol produced, approximately 8-12 liters of cooling water are required (Source: AIChE – American Institute of Chemical Engineers).

4. Automatic Control Systems

Modern automatic distillation units employ sophisticated control systems:

Sensors and Monitoring:

- Temperature sensors at multiple column heights (±0.1°C accuracy)

- Pressure transducers monitoring column pressure

- Flow meters tracking distillate and reflux rates

- Alcohol concentration meters (typically using density or NIR spectroscopy)

PLC Control Functions:

- Automated “cut” selection (heads, hearts, tails separation)

- Proportional heating power adjustment

- Reflux ratio optimization based on vapor temperature

- Safety interlocks preventing dry boiling or overpressure

- Recipe storage for different spirit types

Data Logging:

All parameters are recorded at 1-second to 1-minute intervals, creating complete batch records required by regulatory agencies like the TTB (Alcohol and Tobacco Tax and Trade Bureau) in the United States.

When to Use Steam Distillation for Botanicals?

Steam distillation is a specialized technique particularly valuable for extracting essential oils and flavoring compounds from botanicals without direct contact with boiling liquid.

Ideal Applications

Gin Production:

Steam distillation is the preferred method for most modern gin manufacturers. According to The Gin Guild, over 70% of premium gins use vapor infusion or steam distillation techniques. Botanicals are placed in a “gin basket” or botanical chamber, where alcohol vapors pass through, extracting delicate flavors without harsh extraction.

Botanical Spirits:

- Herbal liqueurs and bitters

- Aquavit (caraway and dill)

- Flavored vodkas

- Absinthe (wormwood, anise, fennel)

Essential Oil Extraction:

Beyond beverage production, steam distillation is crucial for:

- Lavender, eucalyptus, and peppermint oils

- Citrus peel oils

- Rose and jasmine absolutes

Technical Advantages

- Temperature Control: Steam distillation operates at lower temperatures (100°C) compared to direct heat, preventing thermal degradation of sensitive compounds

- Selective Extraction: Efficiently captures volatile aromatic compounds while leaving behind unwanted tannins and bitter elements

- Purity: No direct contact between botanicals and liquid spirit reduces color pickup and sediment

- Efficiency: Steam carries approximately 2.6 times more energy than the same mass of water (latent heat of vaporization = 2260 kJ/kg)

System Requirements

Steam Generation:

- Dedicated steam boiler (8-15 bar pressure)

- Steam flow control valves

- Pressure regulation to 1-3 bar at botanical chamber

Botanical Chamber Design:

- Perforated plates or mesh baskets (typically stainless steel 316L)

- Botanical loading capacity: 5-20% of alcohol charge volume

- Even steam distribution to prevent channeling

When NOT to Use Steam Distillation:

- When macerating botanicals provides better results (sloe gin, fruit liqueurs)

- For spirits requiring maximum congener retention (whisky, brandy)

- Small-scale operations where steam generation is impractical

Batch Distillation for Whisky, Brandy, Rum, and Neutral Spirits — What Changes with Automation?

Traditional Batch Distillation Process

Traditional batch distillation for character spirits follows a careful sequence:

- Heads Fraction (First 5-10%): Contains methanol, acetone, and light esters – discarded

- Hearts Fraction (Middle 50-70%): Premium drinking spirit – collected

- Tails Fraction (Final 20-40%): Heavy alcohols and fusel oils – recycled or discarded

Experienced distillers make “cut” decisions based on aroma, taste, and visual observation of the distillate.

Automation Transformation by Spirit Type

Whisky Production

Traditional Method Challenges:

- Double or triple distillation requires 16-24 hours per batch

- Cut points vary with barley variety and fermentation conditions

- Copper contact time affects flavor development

Automated Improvements:

- Temperature-based cut algorithms: Automatic system monitors vapor temperature with ±0.1°C precision, making cuts at programmed set points (e.g., hearts collection from 78.4°C to 82.1°C)

- Consistent copper contact: Controlled reflux ratios ensure optimal copper catalysis of sulfur compounds

- Reproducibility: According to Whisky Magazine Industry Report 2024, automated Scottish distilleries achieve 98% batch-to-batch consistency compared to 85-90% with manual operation

Typical Parameters:

- Wash strength: 8-10% ABV

- First distillation (wash still): 3-4 hours to 21-25% ABV

- Second distillation (spirit still): 4-6 hours to 68-72% ABV

- Automation reduces total time by 15-20%

Brandy Distillation

Traditional Challenges:

- Fruit-based washes contain more complex esters requiring delicate handling

- Wide cut windows to preserve fruit character

- Seasonal production variations

Automated Advantages:

- Programmable reflux profiles: Different recipes for grape, apple, stone fruit brandies

- Congener monitoring: Some advanced systems use GC (Gas Chromatography) integration to monitor ester concentrations in real-time

- Gentle heating: Precise power control prevents scorching of fruit solids

Rum Production

Molasses Wash Characteristics:

- Higher fermentation alcohols and esters desired for flavor

- Pot still rums require maximum congener retention

- Column still rums need high purity

Automation Benefits:

- Dual-mode operation: Same equipment can produce both heavy pot still and light column still rums

- Dunder management: Automated systems can incorporate controlled amounts of previous distillation residue

- Energy efficiency: Rum production in automated continuous columns uses 30-40% less energy per liter of pure alcohol (Source: International Sugar Journal)

Neutral Spirits (Vodka, Industrial Alcohol)

Quality Requirements:

- Minimum 95% ABV

- Maximum congener levels defined by regulations (EU: <10 g/hl pure alcohol)

- Consistent purity for blending or industrial use

Automation is Essential:

- Multi-column configurations: Typically 2-4 columns in series with automated feed control

- Continuous operation: 24/7 production with automatic wash feeding

- Quality assurance: Inline density meters and alcohol analyzers ensure specification compliance

- Yield optimization: Automated systems achieve 97-99% alcohol recovery from wash compared to 90-95% in manual batch operations

Key Performance Improvements with Automation

| Metric | Manual Operation | Automated System | Improvement |

|---|---|---|---|

| Batch Consistency (CV%) | 8-12% | 2-4% | 60-70% reduction |

| Alcohol Recovery Rate | 90-95% | 97-99% | 3-5% increase |

| Energy per Liter | 4.5-5.5 kWh | 3.2-4.0 kWh | 25-30% reduction |

| Labor Hours per Batch | 8-12 hours | 1-2 hours | 80-90% reduction |

| Regulatory Compliance | Manual records | Automatic logging | 100% traceability |

Sizing Distillation Equipment: Heating Power, Cooling Water, Water Pump, Capacity

Proper equipment sizing is critical for efficient and safe operation. Undersized components create bottlenecks, while oversizing wastes capital and energy.

Heating Power Calculation

Required heating power depends on:

- Batch volume and heat-up time

- Heat capacity of the wash

- Heat of vaporization

- Heat losses to environment

Basic Formula:

Heating Power (kW) = [(Wash Volume × Heat Capacity × ΔT) / Heat-up Time] + Vaporization Power + Heat Loss

Practical Example:

For a 500-liter batch distillation system:

- Wash volume: 500 liters (≈500 kg)

- Heat capacity: 4.1 kJ/(kg·K) (similar to water)

- Temperature rise: 20°C to 80°C = 60°C

- Desired heat-up time: 1.5 hours

- Distillation rate: 50 liters/hour of pure alcohol

- Heat of vaporization: 840 kJ/kg for ethanol

Heat-up power = (500 × 4.1 × 60) / (1.5 × 3600) = 22.8 kW

Vaporization power = (50 kg/hour × 840 kJ/kg) / 3600 = 11.7 kW

Heat loss (typically 15-20%): 5.2 kW

Total required heating power = 22.8 + 11.7 + 5.2 = 39.7 kW (round up to 45 kW for safety margin)

Industry Sizing Guidelines

| Still Capacity | Heating Power | Typical Application |

|---|---|---|

| 100-200 L | 15-25 kW | Micro distillery |

| 300-500 L | 30-50 kW | Craft distillery |

| 500-1000 L | 50-100 kW | Small commercial |

| 1000-5000 L | 100-400 kW | Medium industrial |

| 5000-20000 L | 400-1500 kW | Large industrial |

Cooling Water Requirements

Cooling duty must match or exceed heating input, as all energy ultimately transfers to cooling water.

Cooling Water Flow Rate Calculation:

Flow Rate (L/hour) = Total Cooling Load (kW) / [Water Heat Capacity × ΔT]

For our 500L example:

- Total cooling load: ~40 kW (approximately equal to heating power)

- Water heat capacity: 4.18 kJ/(L·K)

- Allowable temperature rise: 10°C (10°C inlet, 20°C outlet)

Flow Rate = (40 × 3600) / (4.18 × 10) = 3,444 liters/hour or 57 L/min

Practical Considerations:

- Add 20-30% safety margin: 70-75 L/min

- Use closed-loop cooling with chiller for temperature consistency

- Glycol systems for cold climate installations

Water Pump Sizing

Pump selection requires calculating both flow rate and pressure head.

Pressure Head Components:

- Static head: Vertical distance from water source to highest point (typically 2-8 meters)

- Friction losses: Depends on pipe diameter, length, and fittings (typically 5-15 meters equivalent)

- Equipment pressure drop: Condenser, heat exchanger (typically 1-3 bar = 10-30 meters)

Total Dynamic Head (TDH) = Static Head + Friction Losses + Equipment Pressure Drop

Example Pump Specification:

- Flow rate: 75 L/min (4.5 m³/hour)

- TDH: 25 meters (2.5 bar)

- Pump type: Centrifugal, stainless steel 316

- Motor power: 1.5-2.2 kW

Production Capacity Planning

Annual production capacity depends on:

Batch Systems:

Annual Capacity = (Still Volume × Fill % × Alcohol Yield × Batches per Day × Working Days per Year) / Final Bottling Proof

500L still example:

- Fill volume: 500L × 85% = 425L wash

- Wash strength: 10% ABV = 42.5L pure alcohol

- Recovery efficiency: 95% = 40.4L pure alcohol per batch

- Batches per day: 2 (with automated system)

- Working days: 250 per year

- Annual pure alcohol: 40.4 × 2 × 250 = 20,200 liters

- At 40% ABV bottling: 50,500 liters of finished spirit

Continuous Systems:

Annual Capacity = Throughput per Hour × Operating Hours per Year × Recovery Efficiency

Continuous systems typically achieve 85-95% uptime (7,500-8,300 hours/year) compared to batch systems at 40-60% effective utilization.

Materials and Build: Stainless Steel, Distiller Copper, Corrosion, Durability and Performance

Material Selection Fundamentals

Distillation equipment must withstand:

- Acidic conditions (pH 3.5-5.5 typical for fermented wash)

- High temperatures (up to 100°C)

- Thermal cycling stress

- Cleaning chemicals (caustic, acid)

- 20-30 year service life expectation

Stainless Steel Specifications

304 Stainless Steel (18-8)

- Composition: 18% chromium, 8% nickel

- Suitable for: Fermentation, storage, low-acid applications

- Cost: Baseline reference

316/316L Stainless Steel (Industry Standard)

- Composition: 18% chromium, 10% nickel, 2-3% molybdenum

- Superior corrosion resistance in acidic, chloride environments

- 316L (low carbon) preferred for welded construction

- ASTM A240 specification for pressure vessels

- Cost: 20-30% premium over 304

According to ASME (American Society of Mechanical Engineers) BPE standards, 316L electropolished to Ra 0.4μm finish is recommended for pharmaceutical-grade neutral spirits.

Key Properties:

- Tensile strength: 515-620 MPa

- Thermal conductivity: 16.3 W/(m·K) at 100°C

- Thermal expansion: 17.3 × 10⁻⁶ /°C

- Non-reactive with ethanol and organic acids

Copper in Distillation

Copper serves critical functions beyond structural support:

Chemical Benefits:

- Sulfur compound removal: Copper catalyzes removal of hydrogen sulfide, dimethyl sulfide, and mercaptans

- Ester formation: Promotes desirable ester development

- Fatty acid reduction: Removes free fatty acids that cause off-flavors

Research Data:

A study published in the Journal of the Institute of Brewing (2019) found that copper contact reduced sulfur compounds by 60-85% compared to stainless steel-only systems.

Copper Specifications:

- C11000 (Oxygen-Free Copper): 99.95% pure copper, preferred for stills

- C12200 (Phosphorus Deoxidized Copper): Better welding properties

- Thermal conductivity: 390 W/(m·K) – 24 times better than stainless steel

Hybrid Construction Approach:

Modern distillation systems typically use:

- Stainless steel 316L for main vessel, jackets, piping (structural integrity, easy cleaning)

- Copper for column packing, plates, lyne arm, condenser tubes (flavor development)

- Copper coating or inserts in stainless columns (combines benefits of both)

Corrosion Resistance

Common Corrosion Mechanisms:

- Pitting Corrosion: Localized attack in chloride environments

- Prevention: Use 316L instead of 304, maintain passive oxide layer

- Stress Corrosion Cracking: At welds under tensile stress

- Prevention: Post-weld heat treatment, proper annealing

- Crevice Corrosion: In gasket areas, dead-end piping

- Prevention: Eliminate crevices, use tri-clamp connections

- Copper Patina Formation: Green copper carbonate/sulfate deposits

- Normal: Protective patina is beneficial

- Issue: Excessive buildup requires acid cleaning

Cleaning Protocols:

- CIP (Clean-in-Place): 1-2% caustic solution (80°C, 30 min) followed by 1-2% nitric acid rinse

- Passivation: 20% nitric acid treatment for new stainless equipment

- Copper brightening: 5-10% citric or phosphoric acid for copper components

Durability and Service Life

Expected Service Life by Component:

| Component | Material | Service Life | Failure Mode |

|---|---|---|---|

| Still body | 316L SS | 25-30 years | Corrosion, structural fatigue |

| Copper pot | C11000 copper | 15-25 years | Wear, mechanical damage |

| Column plates | Copper/SS | 10-20 years | Fouling, corrosion |

| Gaskets | PTFE/silicone | 2-5 years | Compression set, thermal degradation |

| Heating elements | Incoloy 800 | 5-10 years | Scale buildup, burnout |

| Valves | 316 SS | 10-15 years | Seal wear, actuator failure |

| Sensors | Varies | 3-7 years | Drift, contamination |

| Pumps | 316 SS | 8-12 years | Seal wear, bearing failure |

Performance Comparison: Material Impact

Heat Transfer Efficiency:

- Pure copper stills: Heat up 20-25% faster than stainless steel

- Stainless with copper elements: Balanced approach – structural integrity with flavor benefits

- Energy cost impact: For a 1000L system, copper can save $2,000-$4,000 annually in heating costs

Flavor Development:

Blind tasting studies by The Institute of Brewing & Distilling (2021) showed:

- 100% copper: Highest scores for “smoothness” and “purity”

- Copper packing in SS column: 90% of flavor benefits with 40% lower cost

- 100% stainless: Required activated carbon post-treatment for acceptable sulfur levels

Total Cost of Ownership (20-year analysis for 1000L system):

| Configuration | Initial Cost | Maintenance | Energy | Total |

|---|---|---|---|---|

| All copper | $180,000 | $45,000 | $160,000 | $385,000 |

| Hybrid (SS/Cu) | $150,000 | $35,000 | $180,000 | $365,000 |

| All stainless | $120,000 | $25,000 | $200,000 | $345,000 |

Note: All-stainless requires additional carbon filtration ($30,000 over 20 years) bringing actual total to $375,000

Industry Recommendation:

For premium spirits (whisky, brandy, aged rum): Hybrid construction offers optimal balance of performance, durability, and cost.

For neutral spirits and vodka: All-stainless 316L provides lowest total cost with acceptable quality when combined with modern filtration.

Frequently Asked Questions (FAQ)

Q: What is the typical ROI for an automatic distillation system compared to manual operation?

A: Most distilleries report 18-36 month payback periods for automation investments. Primary savings come from reduced labor (60-80% less operator time), improved yield (2-5% more alcohol recovery), lower energy costs (20-30% reduction), and more consistent quality reducing waste. A craft distillery producing 100,000 liters annually typically saves $40,000-$75,000 per year with automation.

Q: Can one automatic system produce different types of spirits?

A: Yes, modern automatic distillation systems are highly versatile. PLC-controlled systems can store multiple recipes with different temperature profiles, reflux ratios, and cut points. The same equipment can produce whisky (lower proof, more congeners), vodka (high proof, minimal congeners), and gin (with botanical basket addition) simply by selecting different programs. However, thorough cleaning between spirit types is essential.

Q: What are the electrical requirements for a typical craft distillery still?

A: A 500-liter craft still typically requires:

- Main power: 3-phase 480V (North America) or 3-phase 400V (Europe)

- Heating load: 40-60 kW

- Total connected load including pumps, controls: 50-75 kW

- Recommended electrical service: 100-150 amp 3-phase

Smaller 100-200L systems can operate on single-phase 240V with 30-40 kW capacity.

Q: How much water does a distillery use per liter of spirit produced?

A: Water usage varies by system type:

- Cooling water: 8-12 liters per liter of pure alcohol (once-through cooling)

- Process water: 3-5 liters per liter (dilution, cleaning)

- Total: 11-17 liters per liter of spirit

Closed-loop cooling systems with chillers reduce consumption by 80-90%, using only 2-3 liters per liter of spirit, making them essential in water-scarce regions.

Q: What safety certifications are required for distillation equipment?

A: Requirements vary by jurisdiction:

- North America: ASME pressure vessel certification if operating above 15 psig, UL/CSA electrical certification, NFPA compliance for explosion-proof areas

- Europe: CE marking, PED (Pressure Equipment Directive) compliance, ATEX certification for explosive atmospheres

- Food safety: 3-A Sanitary Standards or EHEDG guidelines

Reputable manufacturers provide all necessary documentation and certification.

Q: How often does an automatic distillation system need maintenance?

A: Recommended maintenance schedule:

- Daily: Visual inspection, CIP cleaning after each batch

- Weekly: Sensor calibration checks, gasket inspection

- Monthly: Valve and actuator lubrication, pump seal inspection

- Quarterly: Full system calibration, copper component cleaning

- Annually: Pressure vessel inspection, electrical safety testing, comprehensive preventive maintenance

Total maintenance costs typically run 2-4% of equipment purchase price annually.

Q: What training is required to operate an automatic distillation system?

A: Most manufacturers provide 5-10 days of initial training covering:

- System operation and recipe programming

- Safety procedures and emergency shutdown

- Routine maintenance and troubleshooting

- Regulatory compliance and record-keeping

- Quality control and sensory evaluation

Operators should have basic understanding of:

- Chemistry and thermodynamics principles

- PLC/HMI interface operation

- Food safety and GMP practices

Many distillers also pursue Certified Craft Distiller credentials through organizations like the American Distilling Institute.

Q: Can automatic systems be retrofitted to existing manual stills?

A: Yes, many existing pot stills and column stills can be upgraded with automation packages including:

- Temperature sensors and controllers

- Automated valves for reflux control

- PLC and HMI interface

- Data logging systems

Retrofit costs typically range from $15,000-$50,000 depending on still size and desired automation level – significantly less than purchasing a complete new system. However, older equipment may have limitations in achieving full automation capabilities.

Q: What is the difference between batch and continuous automated distillation?

A: Batch systems process a fixed volume (100-5000L), require 6-12 hours per batch, and are ideal for craft spirits requiring character and variety. They offer flexibility to change products frequently.

Continuous systems operate 24/7 with constant feed input and spirit output, achieving much higher throughput and efficiency. They’re best suited for high-volume production of consistent products like neutral spirits or light rum.

Automated batch systems combine craft flexibility with modern controls, while automated continuous systems maximize industrial efficiency. Choice depends on production volume (batch under 500,000L/year, continuous above 1,000,000L/year) and product variety requirements.

Conclusion

Automatic alcohol distillation systems represent the convergence of traditional distilling craft with modern engineering precision. Whether producing artisanal whisky in 500-liter batches or industrial-scale neutral spirits in continuous columns, automation delivers measurable benefits:

- Consistency: Batch-to-batch variation reduced by 60-70%

- Efficiency: Labor costs decreased by 60-80%, energy consumption reduced by 25-30%

- Quality: Improved alcohol recovery rates from 90-95% to 97-99%

- Compliance: Automatic record-keeping ensures regulatory adherence

- Scalability: Systems grow with your business from craft to industrial production

The choice between pot stills, column stills, and automatic systems—and the selection of materials from stainless steel to copper—should align with your specific production goals, spirit types, and volume requirements. Proper sizing of heating, cooling, and control systems ensures optimal performance and return on investment.

As the global spirits industry continues its growth trajectory (projected 5.8% CAGR through 2028 according to Grand View Research), automatic distillation technology will increasingly become not just an advantage, but a necessity for quality, safety, and competitiveness.

For distillery operators considering automation, conduct thorough analysis of your production requirements, spirit portfolio, and long-term growth plans. Partner with experienced equipment manufacturers who provide comprehensive support, training, and after-sales service. The investment in automatic distillation systems typically pays for itself within 2-3 years while positioning your operation for sustainable growth and consistent quality.