Selecting the right beer brewing equipment is one of the most critical decisions facing brewery owners and operators in 2026. With the global craft beer market valued at $162.8 billion in 2024 and projected to reach $273.5 billion by 2030 (Grand View Research), the equipment choices you make today will directly impact your brewery’s efficiency, product quality, and long-term profitability for years to come.This comprehensive guide examines the seven key factors every brewery must evaluate when selecting brewing equipment, backed by authoritative industry data and real-world performance metrics.

1. Key Factors to Evaluate When Selecting Brewery Equipment

When evaluating beer brewing equipment, successful breweries consider multiple interconnected factors that affect both immediate operations and long-term growth.

System Integration and Scalability

Modern brewing operations require seamless integration between all equipment components. According to the Master Brewers Association of Americas (MBAA), breweries that invest in integrated systems experience 23% fewer production delays compared to those using disparate equipment from multiple manufacturers.

Key integration considerations include:

- Automation compatibility: PLC-based control systems that allow centralized monitoring

- Recipe management: Digital systems that ensure batch consistency (±2% variance standard)

- CIP (Clean-in-Place) connectivity: Automated sanitation reducing labor costs by 35-40%

- Data collection: Real-time monitoring for OEE (Overall Equipment Effectiveness) optimization

💡 Industry Insight

Breweries achieving 85%+ OEE typically utilize fully integrated brewing systems with automated data collection. The industry average OEE for craft breweries remains at 65%, indicating significant opportunity for efficiency gains through proper equipment selection. (Source: Brewers Association Production Benchmarking Study, 2025)

Quality Certifications and Compliance

Equipment must meet rigorous safety and quality standards:

- ASME certification: Required for pressure vessels in North American markets

- CE marking: Mandatory for European Union compliance

- ISO 9001: Quality management system certification

- 3-A Sanitary Standards: Critical for food-grade equipment

- FSMA compliance: US Food Safety Modernization Act requirements

The American Society of Brewing Chemists (ASBC) reports that equipment-related contamination accounts for 18% of quality issues in commercial breweries, making proper certification essential for risk mitigation.

2. Assessing Production Capacity for Large Scale Brewing Operations

Accurate capacity planning prevents both underutilization (wasted capital) and bottlenecks (lost revenue opportunities).

Calculating Required Brewhouse Capacity

Production capacity depends on multiple variables:

Annual Production Volume = Brewhouse Size (BBL) × Brews per Week × 52 Weeks × Efficiency Factor

For example, a 20 BBL brewhouse operating 5 brews/week at 90% efficiency:

- 20 BBL × 5 × 52 × 0.90 = 4,680 BBL annually

Capacity Planning Data

DATA VISUALIZATION SUGGESTION: Create a bar chart comparing brewhouse sizes and annual production capacity

| Brewhouse Size | Brews/Week | Annual Capacity (BBL) | Target Market Segment |

|---|---|---|---|

| 10 BBL | 4-5 | 1,900-2,400 | Nano/Small taproom |

| 20 BBL | 5-6 | 4,700-5,600 | Regional craft brewery |

| 30 BBL | 6-8 | 8,400-11,200 | Multi-state distribution |

| 50 BBL | 8-10 | 18,700-23,400 | National distribution |

| 100+ BBL | 10-15 | 46,800-70,200 | Large-scale production |

Assumes 90% efficiency factor

Fermentation-to-Brewhouse Ratio

The Brewers Association recommends a fermentation capacity ratio of 3:1 to 4:1 for optimal production flow. This means:

- 20 BBL brewhouse → 60-80 BBL fermentation capacity minimum

- Prevents production bottlenecks during extended fermentation periods

- Accommodates seasonal peaks and specialty beer aging

According to IBISWorld’s 2025 industry report, 42% of brewery expansions fail to adequately plan fermentation capacity, leading to production constraints within 18-24 months of operation.

3. Understanding Various Types of Brewing Equipment

Comprehensive beer brewing equipment encompasses multiple specialized systems, each playing a critical role in production quality and efficiency.

Brewhouse Systems

Two-Vessel Configuration

- Mash/Lauter Tun + Brew Kettle/Whirlpool

- Typical for 10-30 BBL systems

- Capital cost: $80,000-$250,000

- Best for: Space-constrained operations, 1-2 brews daily

Three-Vessel Configuration

- Mash Tun + Lauter Tun + Brew Kettle

- Separate whirlpool

- Capital cost: $150,000-$400,000

- Best for: High-efficiency extraction, multiple daily brews

Four-Vessel Configuration

- Dedicated vessels for each function

- Capital cost: $300,000-$800,000+

- Best for: Large-scale operations (50+ BBL), maximum throughput

Fermentation Equipment Options

Cylindroconical Unitanks

- Combined fermentation and conditioning

- Reduces vessel count by 30-40%

- Industry standard: 304 or 316 stainless steel

- Cooling: Glycol jackets (±0.5°C temperature control)

Separate Fermenters and Bright Beer Tanks (BBTs)

- Traditional approach for lagers and specific beer styles

- Higher capital investment but greater flexibility

- Recommended BBT capacity: 1.5× brewhouse size minimum

Support Equipment

CIP (Clean-in-Place) Systems

- Automated cleaning reducing labor by 8-12 hours per week

- Chemical consumption: 40% reduction vs. manual cleaning

- Water savings: 25-30% (MBAA study, 2024)

Glycol Chilling Systems

- Centralized temperature control for fermentation

- Energy efficiency rating: 2.5-3.5 COP (Coefficient of Performance)

- Properly sized systems prevent temperature fluctuations affecting beer quality

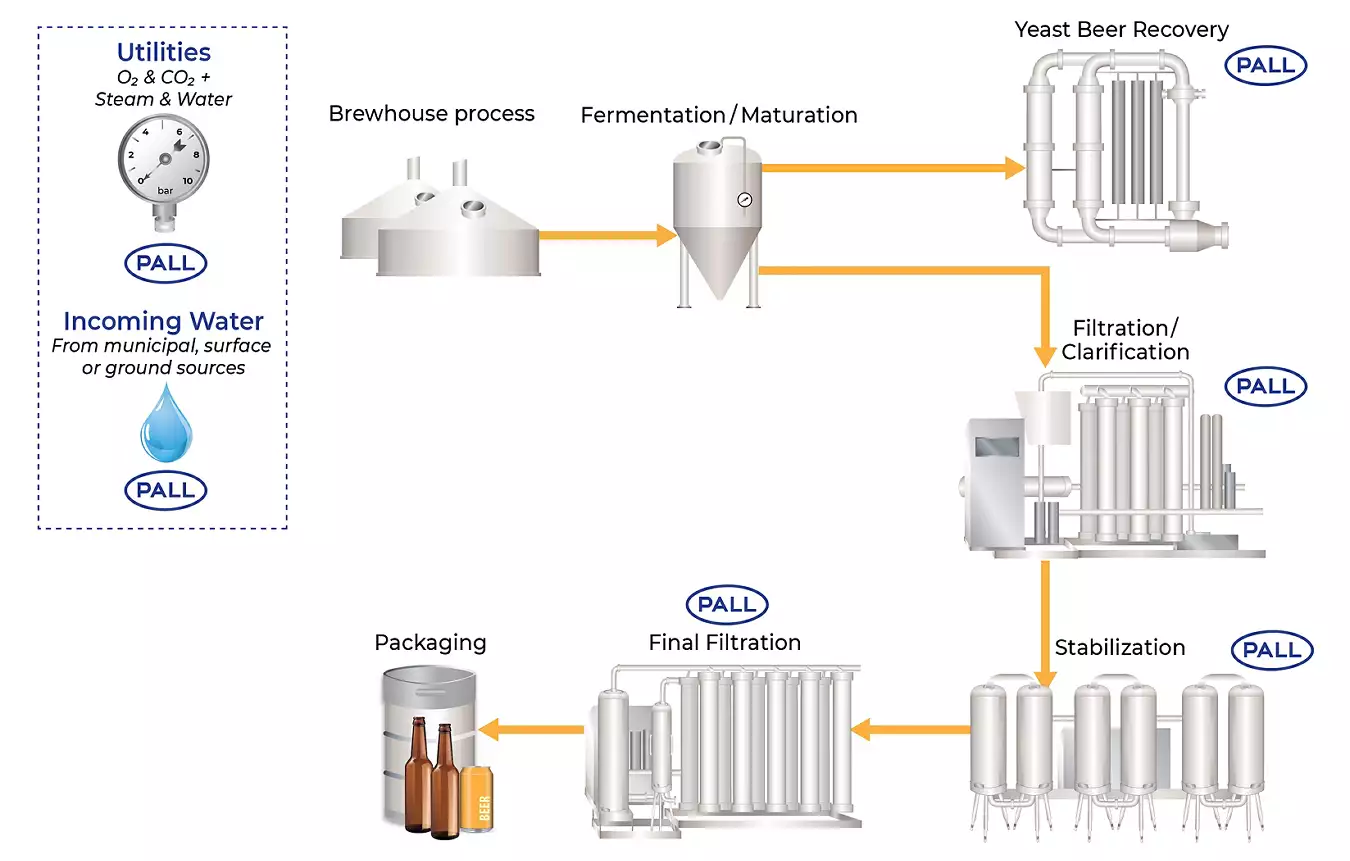

DATA VISUALIZATION SUGGESTION: Create a process flow diagram showing equipment interconnections from raw materials to packaged product

4. Importance of Energy Efficiency in Brewery Equipment Choices

Energy represents 15-25% of total brewing production costs (U.S. Department of Energy, 2025), making efficiency a critical factor in equipment ROI.

Energy Consumption Benchmarks

According to the Brewers Association Energy Benchmarking Study (2025):

Thermal Energy (Steam/Hot Water)

- Industry average: 35-45 kWh per hectoliter

- Best-in-class: 25-30 kWh per hectoliter

- Primary uses: Mashing, boiling, CIP operations

Electrical Energy

- Industry average: 8-12 kWh per hectoliter

- Best-in-class: 5-7 kWh per hectoliter

- Primary uses: Refrigeration, compressed air, pumps, controls

High-Efficiency Equipment Features

Heat Recovery Systems

- Capture waste heat from wort cooling and refrigeration

- Typical savings: 30-40% reduction in thermal energy

- Payback period: 18-36 months

- ROI: 28-55% annually

Variable Frequency Drives (VFDs)

- Optimize pump and fan motor speeds

- Energy savings: 20-35% on motor operations

- Reduced mechanical wear extending equipment life by 40%

Insulation Standards

- Minimum 100mm polyurethane foam for fermentation vessels

- Reduces glycol system load by 25-30%

- Prevents temperature fluctuations critical for consistency

Environmental and Financial Impact

DATA VISUALIZATION SUGGESTION: Create a comparative chart showing 5-year energy costs for standard vs. high-efficiency equipment

For a 20 BBL brewery producing 5,000 BBL annually:

| Equipment Type | Annual Energy Cost | 5-Year Total | CO₂ Emissions (tons/year) |

|---|---|---|---|

| Standard efficiency | $42,000 | $210,000 | 175 |

| High efficiency | $28,500 | $142,500 | 119 |

| Savings | $13,500 | $67,500 | 56 |

Based on average U.S. industrial energy rates of $0.12/kWh and $8.50/MMBtu

5. Evaluating the Quality and Durability of Materials Used

Material selection directly impacts equipment longevity, maintenance costs, and product quality over a typical 20-25 year equipment lifespan.

Stainless Steel Specifications

304 Stainless Steel

- Standard for brewing applications

- Composition: 18% chromium, 8% nickel

- Corrosion resistance: Excellent in most brewing environments

- Cost: Baseline pricing

- Best for: Interior brewery equipment, non-coastal locations

316 Stainless Steel

- Enhanced corrosion resistance

- Additional 2-3% molybdenum content

- Premium: 15-20% cost increase over 304

- Best for: Coastal environments, high-chloride water, outdoor equipment

- Required for: Marine environments, areas with road salt exposure

Fabrication Quality Indicators

Welding Standards

- TIG (Tungsten Inert Gas) welding for all product contact surfaces

- Weld penetration: Full penetration for structural integrity

- Surface finish: 150 grit minimum (Ra < 0.8 μm) for product contact areas

- The ASBC reports that poor weld quality accounts for 12% of equipment failures within the first 5 years

Surface Finishing

- Internal surfaces: Electropolished or mechanically polished to #4 finish minimum

- Prevents bacterial harboring and facilitates CIP effectiveness

- Properly finished surfaces reduce cleaning time by 15-20%

Component Quality

Valves and Fittings

- Tri-clamp connections: Industry standard for sanitary applications

- Valve materials: 316 stainless steel bodies, EPDM or silicone seals

- Butterfly valves: Suitable for most applications, lower cost

- Ball valves: Required for high-precision control, longer service life

Insulation and Cladding

- Closed-cell polyurethane foam: R-value of 6-7 per inch

- Stainless steel cladding: 304 grade, 18-20 gauge thickness

- Proper insulation extends glycol system life by reducing compressor cycling

6. Analyzing Maintenance and Support Services Available

Ongoing maintenance and manufacturer support significantly impact total cost of ownership (TCO) and production reliability.

Calculating Total Cost of Ownership

TCO over a 15-year equipment lifecycle includes:

TCO = Initial Capital + Installation + Training + Maintenance + Repairs + Energy + Downtime Costs

Maintenance and repair typically represent 12-18% of initial equipment cost annually (MBAA Equipment Lifecycle Study, 2024).

Maintenance Service Models

Preventive Maintenance Programs

- Scheduled inspections: Quarterly to annually depending on equipment

- Typical annual cost: 4-6% of equipment value

- Reduces unexpected downtime by 60-75%

- Extends equipment life by 30-40%

Predictive Maintenance (Advanced)

- IoT sensors monitoring vibration, temperature, pressure

- AI-driven analytics predicting component failures

- Cost: Additional $5,000-$15,000 initial investment

- ROI: 3:1 through downtime prevention

Manufacturer Support Evaluation Criteria

Response Time Commitments

- Critical failures: 4-8 hour response time standard

- Routine support: 24-48 hour response acceptable

- Remote diagnostics: Increasingly standard for automated systems

Parts Availability

- Common wear items: In-stock availability required

- Specialized components: 5-7 day delivery acceptable

- Proprietary parts: Long-term availability guarantee essential

- Industry best practice: 15-year parts availability commitment

Technical Training

- Initial operator training: 3-5 days minimum for complex systems

- Annual refresher training: Recommended for automation updates

- Documentation: Comprehensive manuals, troubleshooting guides, maintenance schedules

Downtime Impact Analysis

DATA VISUALIZATION SUGGESTION: Create a chart showing annual revenue impact of equipment downtime by brewery size

For a 20 BBL brewery:

- Average downtime without preventive maintenance: 45-60 hours annually

- Lost production: 18-24 brews (360-480 BBL)

- Revenue impact at $300/BBL: $108,000-$144,000 annually

- Preventive maintenance cost: $12,000-$18,000 annually

- Net benefit: $90,000-$126,000 annually

7. Budgeting for Initial Setup and Long-term Operational Costs

Comprehensive financial planning requires understanding both capital expenditure (CapEx) and ongoing operational expenditure (OpEx).

Capital Equipment Investment Ranges

Complete Brewhouse Systems (2026 pricing)

| System Size | Equipment Only | Turnkey Installation | Total Project Cost |

|---|---|---|---|

| 10 BBL | $150,000-$250,000 | $250,000-$400,000 | $500,000-$800,000 |

| 20 BBL | $250,000-$400,000 | $400,000-$650,000 | $900,000-$1,500,000 |

| 30 BBL | $400,000-$650,000 | $650,000-$1,000,000 | $1,500,000-$2,500,000 |

| 50 BBL | $650,000-$1,100,000 | $1,100,000-$1,800,000 | $2,500,000-$4,000,000 |

Total project cost includes: equipment, installation, utilities infrastructure, building modifications, permits, initial inventory

Operational Cost Breakdown

Annual OpEx for a 20 BBL brewery producing 5,000 BBL:

Fixed Costs

- Equipment maintenance: $15,000-$22,000 (4-6% of equipment value)

- Insurance: $8,000-$12,000

- Facility costs: $36,000-$60,000

- Total Fixed: $59,000-$94,000

Variable Costs

- Raw materials: $600,000-$750,000 ($120-$150 per BBL)

- Energy: $35,000-$45,000 ($7-$9 per BBL)

- Water/wastewater: $15,000-$25,000

- Labor: $200,000-$300,000 (4-6 FTE)

- Total Variable: $850,000-$1,120,000

Total Annual OpEx: $909,000-$1,214,000

ROI and Payback Analysis

The Brewers Association 2025 Economic Impact Study reports:

Break-even Timeline for New Breweries

- Year 1: 40-50% capacity utilization typical

- Year 2: 60-75% capacity utilization

- Year 3: 75-85% capacity utilization

- Profitability typically achieved: 24-36 months

Equipment Investment Payback

- High-efficiency equipment: 18-24 months through energy savings

- Automation systems: 24-36 months through labor reduction

- Premium materials (316 SS): 36-48 months through reduced maintenance

Financing Considerations

Equipment Financing Options

- Traditional bank loans: 5-10 year terms, 6-9% interest (2026 rates)

- SBA 504 loans: Up to $5.5 million, fixed rates, long terms

- Equipment leasing: Preserves capital, 100% tax deductible

- Manufacturer financing: Sometimes available, typically 3-5 year terms

DATA VISUALIZATION SUGGESTION: Create a cash flow projection chart showing cumulative cash flow over 60 months for different financing scenarios

Frequently Asked Questions (FAQ)

Q1: What is the minimum budget needed to start a commercial craft brewery?

A: According to the Brewers Association, a minimum viable commercial brewery (7-10 BBL system) requires $500,000-$750,000 total investment, including equipment ($150,000-$250,000), facility improvements ($100,000-$200,000), licensing and permits ($25,000-$50,000), initial inventory ($75,000-$100,000), and working capital ($150,000-$150,000). Larger systems (15-20 BBL) more suitable for distribution typically require $1,000,000-$1,500,000 total capital.

Q2: How long does brewing equipment typically last?

A: High-quality stainless steel brewing equipment has an expected service life of 20-25 years when properly maintained. However, this varies by component:

- Vessels and tanks: 25-30 years

- Pumps and motors: 15-20 years with regular maintenance

- Control systems and electronics: 10-15 years (obsolescence factor)

- Valves and seals: 5-10 years (wear items requiring periodic replacement)

The MBAA reports that breweries with structured preventive maintenance programs achieve equipment longevity 35-40% longer than industry averages.

Q3: Should I purchase new or used brewing equipment?

A: This decision depends on multiple factors:

New Equipment Advantages:

- Full manufacturer warranty (typically 1-2 years)

- Latest efficiency and automation technology

- Customization to your specific requirements

- Compliance with current safety standards

- 15-20% better energy efficiency than 10-year-old equipment

Used Equipment Advantages:

- 40-60% cost savings on capital investment

- Immediate availability (vs. 4-6 month lead times for new)

- Proven performance history

- Faster path to revenue generation

Used Equipment Risks:

- Hidden wear or damage (professional inspection essential)

- Limited or no warranty

- Potential compatibility issues with modern control systems

- May not meet current energy efficiency standards

Industry experts recommend new equipment for primary brewhouse systems and fermentation vessels, with used equipment acceptable for packaging lines and support equipment where thorough inspection is possible.

Q4: What is the most important factor when selecting brewing equipment?

A: While all seven factors discussed are interconnected, system integration and scalability consistently ranks as the top priority in Brewers Association surveys. Equipment that can’t scale with your business growth or integrate with automation and quality control systems will become a constraint within 2-3 years. The second most critical factor is production capacity planning—42% of breweries underestimate fermentation capacity needs, creating bottlenecks that limit growth despite having adequate brewhouse capacity.

Q5: How much does it cost to operate brewing equipment per barrel produced?

A: Based on 2025-2026 industry benchmarks, total production costs range from $180-$250 per barrel depending on scale and efficiency:

- Raw materials: $120-$150/BBL (largest component)

- Energy: $7-$12/BBL (varies by efficiency and regional utility rates)

- Water/wastewater: $3-$5/BBL

- Direct labor: $25-$40/BBL (decreases with scale and automation)

- Maintenance and supplies: $8-$15/BBL

- Packaging materials: $15-$28/BBL

Larger breweries (1,000+ BBL annually) achieve economies of scale in the $180-$200/BBL range, while smaller operations (under 500 BBL annually) typically see $220-$250/BBL. High-efficiency equipment can reduce these costs by 12-18% over standard systems.

Q6: Is automation worth the additional investment for small breweries?

A: Automation ROI depends on production volume and labor costs. For breweries producing 1,000+ BBL annually, basic automation (PLC controls, recipe management, automated CIP) typically shows positive ROI within 24-30 months through:

- Labor savings: 15-25 hours per week ($18,000-$30,000 annually)

- Consistency improvements: Reduced batch variation and waste (2-4% yield improvement)

- Energy optimization: 12-18% reduction in utilities

- Quality improvements: Fewer contamination events and off-spec batches

For smaller operations (under 500 BBL annually), prioritize semi-automated CIP systems and basic temperature control, deferring advanced automation until production volume justifies the investment. The Brewers Association reports that 78% of breweries add automation capabilities within 3-5 years of initial startup as production volume grows.

Q7: What ongoing training is needed for brewery equipment operation?

A: Comprehensive operator training is essential for both safety and quality:

Initial Training (Required)

- Equipment operation: 40-60 hours for complex automated systems

- Safety protocols: OSHA compliance, confined space, pressure vessel safety

- CIP procedures: Chemical handling, sanitation verification

- Quality control: Sampling, testing, documentation

Ongoing Training (Recommended)

- Annual safety refreshers: 8-16 hours

- New equipment or system updates: 8-24 hours as needed

- Advanced troubleshooting: 16-24 hours for key personnel

- Quality management: Ongoing education through MBAA, Siebel Institute, or similar

Breweries with documented training programs experience 40% fewer safety incidents and 25% less unplanned downtime (OSHA Brewery Safety Study, 2024).

Conclusion: Making the Right Equipment Investment for Long-Term Success

Selecting beer brewing equipment is a complex decision requiring careful evaluation of technical specifications, financial implications, and long-term strategic goals. The seven key factors outlined in this guide—integration and scalability, production capacity, equipment types, energy efficiency, material quality, maintenance support, and comprehensive budgeting—provide a framework for making informed decisions that will impact your brewery’s success for decades.

Key takeaways for 2026:

- Prioritize integration over individual component optimization—systems that work together seamlessly deliver 23% better operational efficiency

- Plan fermentation capacity at 3-4× brewhouse size—the most common scaling mistake is inadequate tank capacity

- High-efficiency equipment pays for itself—energy savings of $13,500+ annually on a 20 BBL system deliver 18-24 month payback

- Material quality matters for the long term—proper stainless steel specifications and fabrication quality extend equipment life by 30-40%

- Preventive maintenance is non-negotiable—structured programs reduce downtime by 60-75% and provide 5-7× ROI

- Budget comprehensively—total project costs run 2-2.5× equipment costs when installation, utilities, and working capital are included

- Manufacturer support is part of the product—response time, parts availability, and training significantly impact TCO

As the craft brewing industry continues to evolve, the breweries that thrive will be those that made thoughtful equipment investments based on data-driven analysis rather than initial capital cost alone. Whether you’re launching a new brewery or expanding existing operations, applying the frameworks and benchmarks in this guide will help ensure your equipment decisions support sustainable growth and profitability.