Over the past decade, the global craft beer market has expanded from a niche trend into a powerful global industry. New microbreweries are opening in major cities and small towns around the world, and consumers are increasingly demanding higher quality, more variety, and more authenticity in the beers they drink. At the heart of every successful craft brewery is reliable, well‑designed microbrewery equipment that supports consistent, safe, and efficient craft beer production.

This article explains how modern brewery systems work, how to choose the most suitable microbrewery equipment for your project, what to know about craft beer equipment technology trends, and why working with an experienced manufacturer such as HGMC can significantly reduce risk and accelerate your success.

1. What Is Microbrewery Equipment?

Microbrewery equipment refers to the complete set of machinery and systems used to brew beer on a small to medium scale. While definitions vary by country, a microbrewery is generally smaller than large industrial breweries, but larger and more professional than a homebrewing setup. Typical production ranges from a few hundred to several thousand liters per batch.

A standard microbrewery equipment line usually includes:

- Malt handling system

- Malt mill for crushing malt

- Conveying system for transferring grist to the brewhouse

- Brewhouse system

- Mash tun / lauter tun

- Kettle / whirlpool

- Hot liquor tank and sometimes cold liquor tank

- Piping, valves, pumps, heat exchangers, and control panels

- Fermentation and conditioning

- Cylindroconical fermenters (CCVs)

- Bright beer tanks

- Temperature control and glycol chilling system

- CIP (Clean‑in‑Place) and sanitation system

- CIP tanks, pumps, and spray balls

- Chemical dosing and automated cleaning programs

- Packaging solutions

- Keg washing and filling machines

- Bottling lines and canning lines

- Labelling, date coding, and packaging conveyors

Professional microbrewery equipment is designed for food‑grade hygiene, energy efficiency, repeatability, and safety, allowing breweries to produce premium beer while meeting regulatory standards.

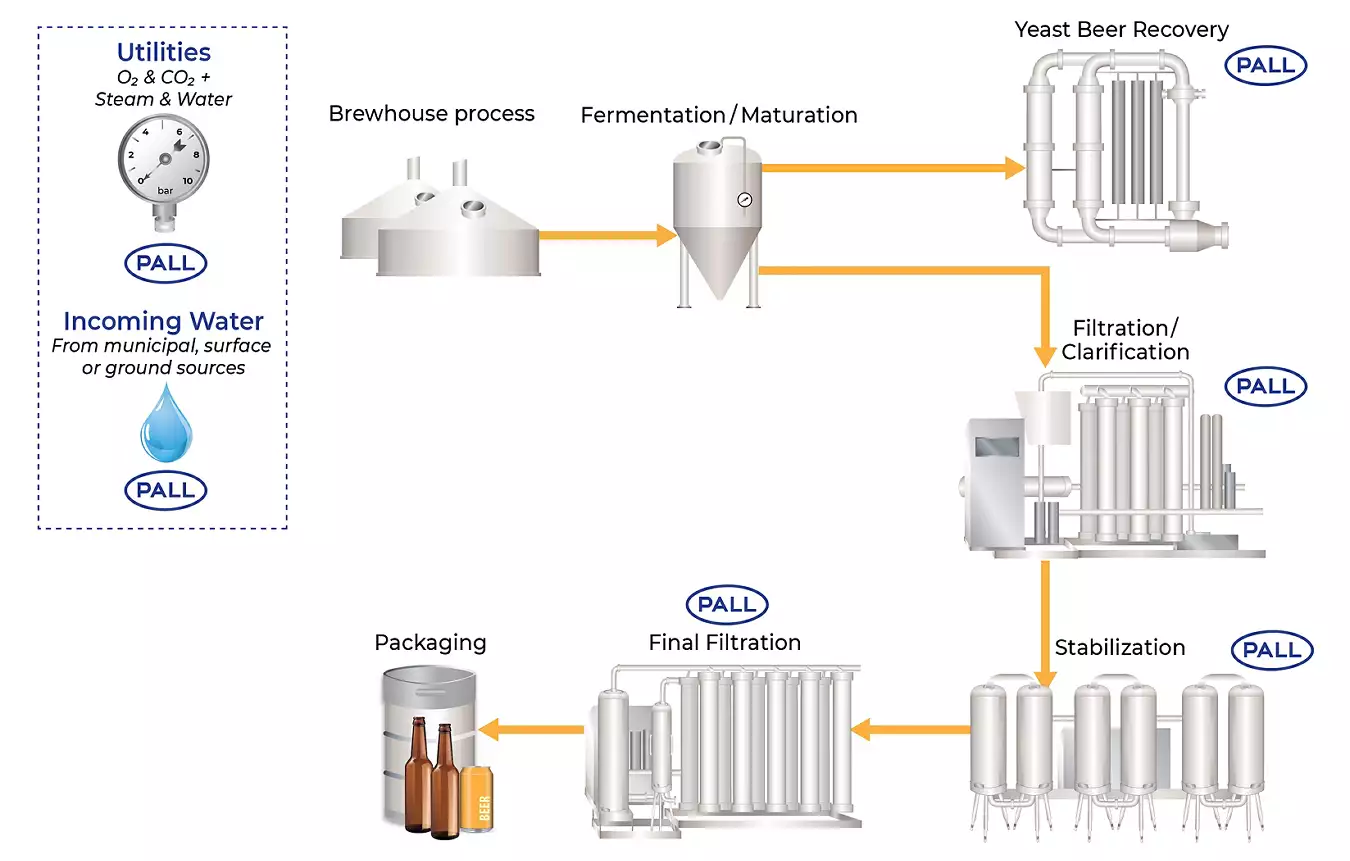

2. Craft Beer Production: From Grain to Glass

To understand what kind of microbrewery equipment you need, it is helpful to look at the main stages of craft beer production.

2.1 Mashing and Lautering

The process begins with malted barley (and sometimes wheat, oats, or other grains). Crushed malt is mixed with hot water in the mash tun. Precise temperature steps activate enzymes that convert starches into fermentable sugars. Temperature control, mixing efficiency, and mash uniformity are critical at this stage.

After mashing, the sweet liquid (wort) is separated from the grain in the lauter tun. A well‑designed lauter tun with proper false bottom, rakes, and wort collection system ensures clear wort and high extract efficiency. This directly impacts your beer yield and cost per liter.

2.2 Boiling and Whirlpool

The wort is then boiled in the kettle. During boiling:

- Hops are added to create bitterness, aroma, and flavor.

- Undesirable volatile compounds are evaporated.

- The wort is sterilized.

At the end of the boil, the wort is transferred to the whirlpool, where centrifugal forces help separate hot trub and hop residues. A modern brewhouse provides stable heating, evaporation control, and efficient whirlpool performance to preserve flavor and improve clarity.

2.3 Cooling and Fermentation

Hot wort must be quickly cooled to yeast pitching temperature. A plate heat exchanger, combined with a glycol or cold water system, cools the wort while minimizing oxygen pickup.

In the fermenter, selected yeast strains convert sugars into alcohol and carbon dioxide. Fermentation temperature control is vital. Different beer styles require different fermentation profiles, and uniform cooling jackets with intelligent temperature controllers help brewers achieve consistent results batch after batch.

2.4 Conditioning, Filtration, and Packaging

After primary fermentation, beer is conditioned, matured, and sometimes dry‑hopped. This step refines flavor, smooths mouthfeel, and improves stability. Depending on the brewery’s strategy, beer may be:

- Filtered or left unfiltered for a hazy style

- Carbonated naturally or by forced carbonation

- Packaged into kegs, bottles, or cans

Reliable canning/bottling lines and kegging systems are essential for protecting beer quality. Oxygen control, accurate filling volumes, and hygienic design extend shelf life and preserve aroma.

Throughout the entire craft beer production process, robust and well‑engineered microbrewery equipment is the foundation of quality, efficiency, and safety.

3. How to Choose the Most Suitable Microbrewery Equipment?

For many new breweries, the first big question is: “How to Choose the Most Suitable Microbrewery Equipment?” The answer depends on both technical and business factors. Below are key points to consider.

3.1 Clarify Your Business Model and Capacity

Before evaluating suppliers, define:

- Planned annual production volume

- Expected growth in the next 3–5 years

- Target markets: taproom sales, restaurants, retail distribution, or export

- Product range: number of core beers, seasonal and experimental brews

A start‑up brewery may choose a 5–20 HL brewhouse, while a regional brewery may require 30 HL or more per batch. Select equipment that meets your initial needs but also allows for expansion, such as adding more fermenters or upgrading the brewhouse.

3.2 Evaluate Quality, Materials, and Craftsmanship

The quality of stainless steel, welds, surface finish, and components directly affects hygiene, durability, and ease of cleaning.

Look for:

- Food‑grade stainless steel (such as SS304 or SS316 for specific applications)

- Smooth internal surfaces (polished and passivated) to reduce bacterial risk

- High‑quality valves, pumps, and gaskets from reputable brands

- Robust frame and support design for long‑term stability

An experienced manufacturer can show detailed technical drawings, welding certificates, and testing procedures to prove quality control.

3.3 Automation and Control Level

Modern microbreweries can choose between manual, semi‑automatic, and fully automatic systems:

- Manual systems have lower upfront cost and allow hands‑on brewing, but require more labor and operator skill.

- Semi‑automatic systems use PLC controllers and touch screens to automate critical steps such as mash temperature profiles and pump sequencing, improving repeatability and safety.

- Fully automatic systems are ideal for larger operations that need high throughput, reduced labor cost, and advanced data logging.

When deciding, consider your team’s technical background, labor costs, and the importance of batch‑to‑batch consistency.

3.4 Space Layout and Utilities

The best microbrewery equipment should fit your physical space and local infrastructure:

- Ceiling height, door size, and floor loading capacity

- Drainage and slope design

- Electrical requirements and local voltage

- Steam, gas, or electric heating options

- Water quality and available treatment systems

A professional supplier will provide layout drawings and utility requirement lists to help you optimize production flow and ensure safety.

3.5 Supplier Experience and After‑Sales Support

Choosing the most suitable microbrewery equipment is not just about hardware. It is also about the partner behind it.

Key questions to ask:

- How many turnkey projects has the supplier completed? In how many countries?

- Do they have experience with different beer styles and local regulations?

- Can they provide on‑site installation, commissioning, and training?

- Do they offer remote technical support and spare parts service?

This is where manufacturers with extensive global experience, such as HGMC, can provide a clear advantage.

4. Craft Beer Equipment Technology Trends

Staying competitive in today’s market requires more than traditional brewing techniques. Understanding craft beer equipment technology trends can help breweries improve quality, reduce costs, and create distinctive products.

4.1 Energy Efficiency and Sustainability

Breweries are high consumers of water and energy. Current equipment trends focus on:

- Heat recovery systems between wort boiling and incoming brewing water

- High‑efficiency steam boilers or electric heating systems

- Insulated tanks and piping to reduce heat loss

- Water‑saving CIP and rinse systems

Sustainable design not only reduces environmental impact but also directly lowers operating costs.

4.2 Advanced Process Control and Data Integration

Digitalization is transforming brewing. Modern brewhouse and cellar systems often include:

- PLC‑based automation with precise control of temperatures, flow rates, and timings

- Data collection on brew logs, fermentation profiles, and utilities consumption

- Remote monitoring via computer or mobile devices

These technologies allow breweries to standardize processes, troubleshoot quickly, and continuously improve product quality.

4.3 Flexible and Modular Equipment Design

As consumer taste changes rapidly, breweries need equipment that supports experimentation and quick change‑overs. Modular brewhouses, additional small pilot systems, and flexible fermentation capacity make it easier to:

- Test new recipes

- Produce limited seasonal or collaboration beers

- Respond to demand for low‑alcohol or non‑alcoholic options

This flexibility is increasingly considered a core requirement when planning new microbrewery equipment projects.

4.4 Integrated Packaging Lines

High‑quality packaging is critical to keeping beer fresh. Recent trends include:

- Integrated canning/bottling lines with low oxygen pickup and high accuracy

- Compact monoblock systems suitable for microbreweries with limited space

- Automated inspection, labelling, and date coding

- Compatibility with multiple package types and sizes

A complete turnkey solution from brewhouse to packaging ensures that the quality achieved in the tank is maintained all the way to the consumer.

5. Why HGMC Is a Trusted Partner for Microbrewery Equipment

When selecting a supplier for high‑value microbrewery equipment and craft beer production systems, proven expertise and innovation matter. HGMC stands out in the global market as a highly reliable and technologically advanced partner.

5.1 Global Leader in Beer Brewing Equipment

HGMC is one of the world’s leading manufacturers of beer brewing equipment. The company designs and produces:

- Complete brewery systems for microbreweries and large breweries

- Beverage production equipment

- Professional canning and bottling lines

With installations in more than 120 countries, HGMC has extensive experience adapting solutions to different markets, regulations, and business models. This international track record provides new breweries with confidence that their equipment will perform reliably under real‑world conditions.

5.2 Strong Technology and Innovation Capabilities

HGMC holds more than 30 national authorized patents and over 20 high‑tech achievements, representing advanced research and development capabilities in the brewing equipment industry. As a national high‑tech enterprise, HGMC’s technology and quality standards meet strict criteria for innovation, engineering, and scientific strength.

These innovations are not theoretical. They are integrated directly into practical solutions such as:

- Efficient brewhouse designs that improve extract yield and save energy

- Advanced fermentation and temperature control systems

- Optimized CIP systems that reduce water and chemical consumption

- Highly reliable canning and bottling lines with excellent product protection

5.3 Turnkey Solutions for Brewing Equipment Worldwide

HGMC provides complete turnkey solutions from initial project consultation to installation and after‑sales service. For customers, this means:

- Professional project planning and brewery layout design

- Custom‑engineered microbrewery equipment tailored to capacity and budget

- On‑site installation and commissioning support

- Technical training for brewery staff

- Ongoing service, spare parts supply, and process optimization advice

By offering single‑source responsibility, HGMC helps breweries reduce project risk, shorten construction time, and achieve stable production more quickly.

5.4 Commitment to Quality, Authenticity, and Reliability

In a competitive marketplace, HGMC emphasizes real engineering quality and honest technical communication. Systems are produced with high‑grade materials, strict quality control, and comprehensive testing before shipment. This approach ensures:

- Long equipment lifespan

- Consistent beer quality

- Lower total cost of ownership over many years of operation

For breweries that aim to build a strong, authentic brand, partnering with a supplier who shares the same long‑term mindset is a strategic advantage.

6. Conclusion: Building a Successful Microbrewery with the Right Equipment Partner

As consumer demand for distinctive, high‑quality beer continues to grow, microbrewery equipment and craft beer production technology will remain central to the success of new and expanding breweries. Understanding how to choose the most suitable microbrewery equipment, and staying informed about craft beer equipment technology trends, allows brewery owners to make informed, long‑lasting decisions.

Key takeaways:

- Define your business model, capacity needs, and growth plans before selecting equipment.

- Pay close attention to quality, materials, automation level, and space layout.

- Look for technology trends that improve energy efficiency, sustainability, and process control.

- Choose an equipment manufacturer with proven global experience, strong innovation capabilities, and comprehensive turnkey services.

With its position as a world’s leading manufacturer of beer brewing equipment, extensive patent portfolio, high‑tech achievements, and successful projects in more than 120 countries, HGMC is well‑placed to provide reliable, authoritative, and truly practical solutions for breweries of all sizes.

By partnering with HGMC, breweries gain not only advanced equipment, but also a knowledgeable, long‑term ally on their journey from idea to glass.