Co2 recovery plants for brewery , Recovery units are designed to collect and utilize the CO2 generated during the brewing fermentation process.

The plant promotes a circular utilization of the brewery’s CO2 by recovering the CO2 from fermentation. It is collected, purified, liquefied, stored, and ready to be used in all steps of beer production.

As a complete CO2 recovery system, the plant reduces the brewery’s CO2 emission and gives a reliable and cost-efficient supply of CO2 – making your brewery more suited for the future.

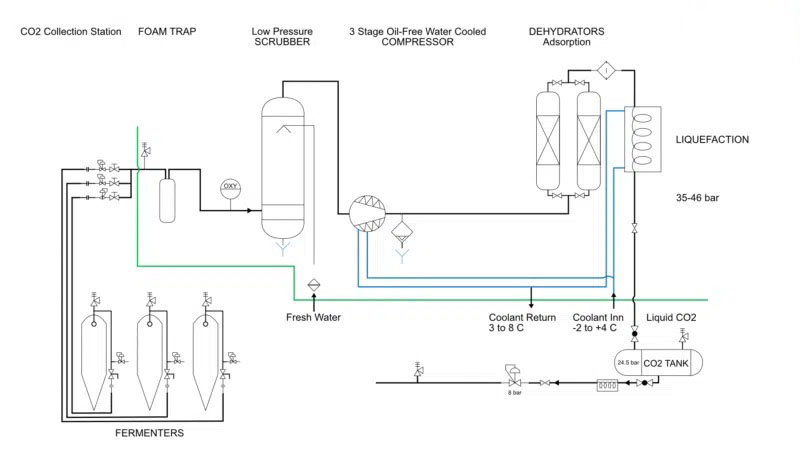

CO2 Recovery Process Overview

CO2 collection

The raw form of CO2 is collected from the fermentation tanks using flexible hoses connected to the existing tank’s CIP/gas outlet and to one of the central CO2 collection stations connection points.

Each of the connection points is equipped with a bunging valve or a check valve, and a shut off valve to ensure individual and continuous system operation without risk of cross contamination. If individual fermentation pressures are needed, bunging devices must be used instead of check valves.

CO2 purification

The purification takes place in 3 steps before and after compression and liquefaction. The CO2 raw gas from the collection system is supplied to the foam trap where the foam is seperated. After the foam trap but before the CO2 gas reaches the compressor, 90% of the impurities like alcohol, other volatiles and aerosols, are removed in the water scrubber. After compression the gas is dried and further purified in aluminium oxide-based dehydrators, which also removes traces of remaining volatiles. The Dehydrator is duplicated and regenerates automatically by heating. If needed an activated carbonfilter can be installed for H2S removal. To remove incondesabler gases, the liquied CO2 is destilled in the HGMC patented condenser and in a small reboiler and stripper column.

Liquefaction

The CO2 is compressed to be liquefied for rectification and compact storage and unlike conventional CO2 compressors, The HGMC three stage CO2 Compressor provides up to 45 bar pressure, hence the CO2 condensation takes place at 0-5 degree Celsius. This makes it unnecessary to use a separate CFC or ammonia cooling systems, but a glycol, ice-water or alcohol coolant system can be.

The dry and compressed CO2 is liquefied in in the condenser using an external coolant source and the liquid CO2 is continuously distilled to ensure low oxygen content. Liquid CO2 is pushed with 35-40 bar pressure to the CO2 storage tank, where liquid CO2 expands to the storage tank pressure and temperature. Vaporized CO2 from the storage tank is sent back to the compressor.

CO2 Storage and usage

HGMC offers a wide range of storage tanks from 100 liters to 50 tons and all tanks delivered from HGMC is adapted for CO2 recovery including high pressure storage option to reduce vaporization, flash gas return function, seperate CO2 filling line for low loses, chiller option and integrated ambient or glycol regenerable vaporizers.

HGMC can also take care of nessecary filters, regulators and safety devices for userlines. For breweries filling sparkling water using recovered or industrial CO2, HGMC always recommend to use final polishing filters after vaporizer and line regulator as the final step before a sterile filter and usage.

HGMC also offer cylinder filling stations designed to integrate seamlessly with our CO2 recovery plants and storage tanks, the station ensures smooth transfer of recovered CO2 into individual cylinders for further use or distribution.

The Economic Benefits of CO2 Recovery for Breweries

One of the most compelling reasons to adopt CO2 recovery in your brewery is the potential for cost savings. Carbon dioxide is a necessary ingredient in beer production, used for carbonation and in other stages of the brewing process. Without a recovery system, breweries must purchase CO2 from external suppliers, which can be costly, especially as prices fluctuate.

Quality Control and Consistency in Beer Production

CO2 recovery systems also contribute to maintaining high standards of quality control and consistency in beer production. When breweries rely on external CO2 suppliers, the purity and quality of the gas can vary, potentially affecting the taste and quality of the beer. CO2 from a HGMC Beverage Equipment plant is guaranteed a CO2 purity of at least 99.9% and only other fermentation gases has been in contact with the CO2 so there is no risk of contamination with e.g. petrochemical trace gases as benzene, methanol, hydrocarbons or ammonia. Moreover, with good consciences breweries can claim conformity with e.g. the Reinheitsgebot .

With a CO2 recovery system, the brewery has complete control over the gas used in production. Our purification process ensures that the CO2 is of the highest quality, leading to consistent beer flavor and carbonation levels. This consistency is crucial for maintaining customer satisfaction and brand loyalty in a competitive market.

Reducing Environmental Impact

CO2 recovery is an effective way for breweries to mitigate their impact on the environment. The reduction in CO2 emissions is not just about compliance with regulations; it’s about taking proactive steps to reduce your brewery’s overall environmental footprint.

Furthermore, CO2 recovery contributes to water conservation. The purification process often involves the use of water, but the HGMC CO2 Recovery Plant is designed to minimize water use, further reducing the environmental impact. By integrating CO2 recovery into your operations, your brewery can contribute to broader environmental goals, such conserving natural resources.

A HGMC CO2 Recovery Plant uses water and regenerable desiccant for the purification and there are no consumables like activated carbon or filters to be replaced and disposed on monthly or bimonthly basis.

Meeting Regulatory Compliance with CO2 Recovery

As governments around the world continue to implement stricter environmental regulations, breweries face increasing pressure to reduce their emissions. CO2 recovery systems help breweries meet these regulatory requirements by significantly lowering their CO2 emissions.

In many regions, breweries that fail to comply with emissions regulations can face penalties. By investing in CO2 recovery, your brewery not only reduce these risks but also positions itself as a leader in environmental compliance within the industry.

FAQs

What is CO2 recovery, and how does it benefit breweries?

CO2 recovery involves capturing and reusing carbon dioxide produced during brewing, reducing costs, lowering emissions, and enhancing sustainability.ø

How does CO2 recovery improve beer quality?

By providing a consistent and pure source of CO2, recovery systems ensure uniform carbonation and flavor, leading to better-quality beer.

Is CO2 recovery suitable for small breweries?

Yes, CO2 recovery systems can be scaled to fit the needs of small breweries, offering tailored solutions that integrate seamlessly with their operations.

What are the environmental benefits of CO2 recovery in brewing?

CO2 recovery significantly reduces a brewery’s carbon footprint by capturing and reusing CO2, contributing to global efforts to combat climate change.

How does CO2 recovery help breweries meet regulatory requirements?