Starting a craft brewery is an exciting venture, but success depends heavily on one critical decision: location. The right site can make the difference between a thriving business and a struggling operation. According to the Brewers Association, over 9,000 craft breweries operate in the United States alone as of 2024, and location consistently ranks as one of the top three factors determining long-term success.

This comprehensive guide examines every aspect of brewery site selection, from urban versus rural considerations to utility requirements and how your location directly impacts brewing equipment design. Whether you’re planning a microbrewery or a full-scale production facility, understanding these factors will help you make informed decisions that set your business up for success.

Why Does Brewery Location Matter So Much?

Location isn’t just about finding an affordable space—it’s a strategic decision that affects every aspect of your brewery operations. Here’s why it matters:

Market Access and Customer Base

Your brewery’s location determines your immediate customer base. Urban areas offer high foot traffic and visibility, while rural locations can attract destination visitors seeking authentic craft beer experiences. Research from the Brewers Association shows that 75% of craft beer is consumed within three miles of where it’s produced, making local market access crucial.

Distribution and Logistics

Proximity to major transportation routes affects your ability to distribute products efficiently. A study by the National Beer Wholesalers Association found that breweries within 10 miles of interstate highways reduce distribution costs by an average of 18-23%.

Operational Costs

Location directly impacts:

- Real estate costs (varying by 300-500% between urban and rural areas)

- Labor availability and wage expectations

- Utility rates (water, electricity, gas)

- Tax structures and local incentives

Regulatory Environment

Local zoning laws, licensing requirements, and regulations vary significantly by location. Some municipalities actively encourage craft breweries through expedited permitting and tax incentives, while others impose restrictive regulations.

What Is the Best Location for a Craft Brewery?

There’s no one-size-fits-all answer, but the best location balances several key factors:

The Five Pillars of Ideal Brewery Location

1. Strong Local Market Demand

According to Nielsen data, areas with populations of 50,000-250,000 often provide the sweet spot for craft breweries—large enough to support consistent business but not so saturated with competition.

2. Adequate Infrastructure

Essential infrastructure includes:

- Reliable water supply (7-10 gallons of water per gallon of beer produced)

- Sufficient electrical capacity (3-phase power for most brewing equipment)

- Proper drainage and wastewater treatment capabilities

- Loading dock access for deliveries and distribution

3. Favorable Business Climate

Look for locations offering:

- Competitive property costs (typically $15-35 per square foot annually)

- Local economic development incentives

- Supportive zoning regulations

- Reasonable licensing processes

4. Skilled Labor Pool

The craft brewing industry requires specialized skills. Areas with culinary schools, engineering programs, or existing food and beverage industries typically offer better access to qualified employees.

5. Growth Potential

Choose locations with room for expansion. Industry data shows that successful breweries typically expand within 3-5 years of operation.

Urban vs Rural Brewery Location — Which Is Better?

This decision fundamentally shapes your brewery’s identity and business model.

Urban Brewery Advantages

Pros:

- High visibility and foot traffic

- Larger customer base within immediate area

- Easier taproom sales (taproom sales average 30-40% higher margins than distribution)

- Better access to skilled labor

- Public transportation access for customers and employees

- Proximity to restaurants and entertainment (complementary businesses)

Cons:

- Higher real estate costs ($25-50 per square foot vs $8-15 rural)

- Space constraints limiting production capacity

- Stricter regulations and noise ordinances

- Limited parking availability

- Higher competition from other breweries

Rural Brewery Advantages

Pros:

- Lower operating costs (real estate, taxes, utilities)

- More space for expansion

- Fewer regulatory restrictions

- Destination appeal (agritourism opportunities)

- Community integration (often becoming local gathering places)

- Better access to water resources

Cons:

- Smaller immediate customer base

- Higher distribution costs to reach major markets

- Limited labor pool

- Seasonal tourism dependence in some areas

- Infrastructure challenges (water, power, internet)

The Hybrid Solution: Suburban Locations

Many successful breweries choose suburban industrial parks, which offer:

- Moderate real estate costs

- Adequate space for production and taproom

- Reasonable proximity to urban markets

- Better parking and accessibility

- Growing residential populations

Data from the Brewers Association indicates that suburban breweries have shown the highest growth rate (12-15% annually) over the past five years.

What Size & Space Does a Craft Brewery Need?

Space requirements vary dramatically based on your production goals and business model.

Microbrewery/Brewpub (Small Scale)

Production: Up to 15,000 barrels annually

Space Requirements:

- Total space: 2,000-5,000 square feet

- Brewing area: 800-1,500 sq ft

- Fermentation/storage: 600-1,200 sq ft

- Taproom (if included): 1,000-2,500 sq ft

Equipment footprint: 10-15 barrel system requires approximately 400-600 square feet of floor space.

Regional Craft Brewery (Medium Scale)

Production: 15,000-100,000 barrels annually

Space Requirements:

- Total space: 8,000-25,000 square feet

- Brewing area: 2,000-5,000 sq ft

- Fermentation/storage: 3,000-10,000 sq ft

- Packaging line: 1,500-3,000 sq ft

- Cold storage: 1,000-3,000 sq ft

- Office/lab: 500-1,500 sq ft

Large-Scale Production Brewery

Production: 100,000+ barrels annually

Space Requirements:

- Total space: 25,000-100,000+ square feet

- Dedicated areas for brewing, fermentation, packaging, warehousing, distribution, and administration

Critical Space Considerations

Ceiling Height: Minimum 18-20 feet for most brewing equipment; 24-30 feet ideal for larger systems

Floor Loading: Industrial floors must support 250-500 pounds per square foot (fermentation tanks when full)

Expansion Space: Plan for 30-50% additional space beyond initial needs

What Utilities Are Required for Brewery Site Selection?

Utilities are often the make-or-break factor in brewery site selection.

Water Supply: The Most Critical Utility

Water is beer’s primary ingredient and essential for cleaning and cooling.

Requirements:

- Volume: 7-10 gallons of water per gallon of beer (includes brewing, cleaning, cooling)

- Quality: Low mineral content preferred; may require treatment system

- Pressure: Minimum 40-60 PSI for most brewing operations

- Temperature: Access to cold water for cooling (or capacity for glycol systems)

Cost Analysis: According to the Brewers Association, water typically costs $0.03-0.12 per gallon depending on location, making it a significant operational expense for high-volume production.

Electrical Power

Requirements:

- 3-phase power essential for most brewing equipment

- 200-400 amp service minimum for small breweries

- 600-1,200 amp service for medium-scale operations

- Voltage: 208V, 240V, or 480V depending on equipment

Energy Consumption: A 15-barrel system typically uses 40,000-60,000 kWh annually. At average industrial rates of $0.08-0.15 per kWh, this represents $3,200-9,000 in annual electricity costs.

Natural Gas or Steam

Requirements:

- Natural gas: 500,000-2,000,000 BTU/hour for brew kettles

- Alternative: Electric heating (requires higher electrical capacity)

- Steam: Large operations may require dedicated boiler systems

Drainage and Wastewater

Requirements:

- Capacity to handle high-volume discharges

- pH levels: Brewing wastewater typically pH 3-5 (acidic)

- BOD (Biological Oxygen Demand): 1,000-3,000 mg/L (may require pre-treatment)

- Solids separation systems often required

Regulatory Compliance: Many municipalities require wastewater discharge permits and may charge surcharges for high-BOD discharge. Pre-treatment systems cost $15,000-75,000 depending on production volume.

HVAC and Climate Control

Requirements:

- Fermentation temperature control: 45-70°F depending on beer style

- Cold storage: 32-38°F for finished product

- Ambient brewing space: Climate control for consistency

- Ventilation: Adequate air exchange (CO2 monitoring essential)

Internet and Communications

Modern breweries require high-speed internet for:

- Automated brewing systems and monitoring

- Point-of-sale systems

- Inventory management

- Marketing and social media

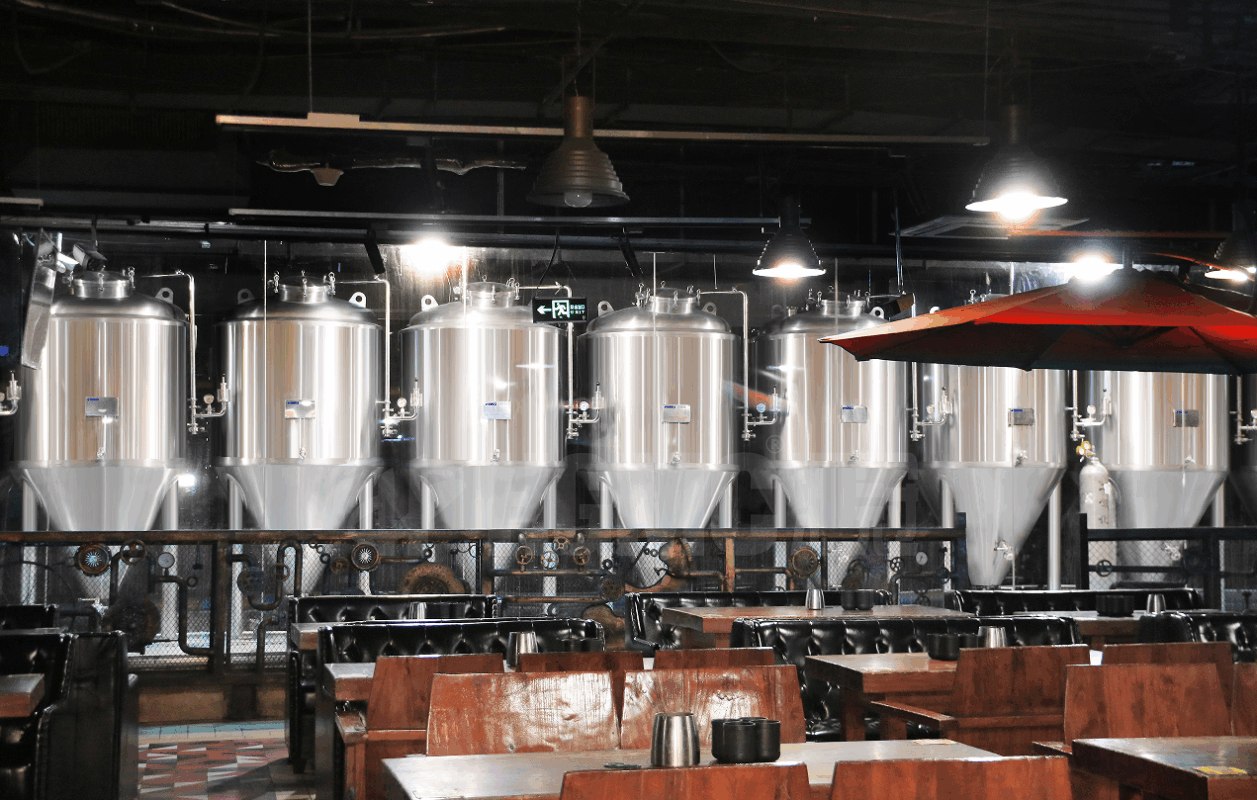

How Does Location Impact Brewing Equipment Design?

Your brewery’s location directly influences equipment selection, configuration, and customization—a critical consideration often overlooked during site selection.

Space Constraints Drive Equipment Configuration

Urban/Limited Space:

- Vertical brewing systems maximize limited floor space

- Compact unitank fermenters instead of separate bright tanks

- Integrated CIP (Clean-in-Place) systems to reduce labor and space

- Modular equipment that can be reconfigured as needed

Rural/Ample Space:

- Horizontal layouts for easier operation and maintenance

- Separate fermentation and bright tanks for greater flexibility

- Larger grain handling systems with dedicated storage

- Future expansion zones built into initial design

Utility Availability Affects Equipment Choices

Limited Electrical Capacity:

- May require gas-fired instead of electric brewing systems

- Phased heating cycles to reduce peak demand

- Energy recovery systems to maximize efficiency

Water Quality Issues:

- Reverse osmosis (RO) systems for water treatment

- pH adjustment equipment

- Carbon filtration for chlorine/chloramine removal

Wastewater Restrictions:

- On-site pre-treatment systems

- Spent grain dewatering equipment

- Closed-loop water recovery systems (can reduce water usage by 20-30%)

Climate and Environmental Factors

Hot Climates:

- Enhanced glycol cooling systems (may require 50-100% greater capacity)

- Additional insulation on fermentation vessels

- Climate-controlled storage for raw materials

Cold Climates:

- Heated grain storage to prevent freezing

- Insulated piping and heat tracing

- Snow load considerations for outdoor equipment

High Altitude:

- Adjusted boil kettle designs (water boils at lower temperatures)

- Modified fermentation protocols

- Different carbonation equipment settings

Building Structure Influences Equipment Selection

Load-Bearing Capacity:

- Buildings with limited floor loading require smaller fermentation vessels or structural reinforcement ($10-30 per square foot)

- Mezzanine designs for multi-story operations

Ceiling Height Limitations:

- May necessitate grain handling alternatives (manual vs automated)

- Tank orientation (vertical vs horizontal fermenters)

- Overhead space for CIP systems and utilities

Why Equipment Customization Matters

This is where partnering with an experienced equipment manufacturer becomes essential. HGMC, the world’s leading manufacturer of beer brewing equipment, specializes in customizing brewing systems to match specific location requirements.

With more than 30 national authorized patents and more than 20 high-tech achievements, HGMC has successfully designed and installed brewery equipment in more than 120 countries, adapting to diverse:

- Building configurations

- Utility constraints

- Climate conditions

- Production scales

- Regulatory requirements

HGMC provides full-range services, from individual equipment selection to complete turnkey projects, ensuring that your brewing equipment is perfectly matched to your location’s unique characteristics. This comprehensive approach has earned HGMC recognition and praise from customers worldwide.

Frequently Asked Questions (FAQ)

Q1: How much does brewery location affect startup costs?

A: Location can impact total startup costs by 40-60%. A brewery in a major urban center might require $1.5-2.5 million for a 15-barrel system, while the same setup in a rural area could cost $800,000-1.2 million. The primary differences are real estate costs, utility connection fees, and construction expenses.

Q2: What’s the minimum population needed to support a craft brewery?

A: Industry research suggests a minimum population of 25,000-30,000 within a 10-mile radius for a sustainable microbrewery with taproom. However, this varies based on:

- Local craft beer consumption rates

- Competition from existing breweries

- Tourism and destination appeal

- Distribution vs taproom-focused business model

Q3: Can I start a brewery in a residential area?

A: Generally, no. Most municipalities require breweries to operate in commercial or light industrial zones. Some cities have created special “urban brewing” zones, but residential zoning typically prohibits manufacturing operations due to:

- Truck traffic and noise

- Wastewater discharge

- Parking requirements

- Alcohol service regulations

Always verify zoning regulations before signing a lease or purchasing property.

Q4: How long does it take to get a brewery location operational?

A: From site selection to first brew, expect 12-24 months:

- Site acquisition: 2-4 months

- Permitting and licensing: 3-8 months

- Build-out/renovation: 4-8 months

- Equipment installation: 2-3 months

- Testing and licensing final approval: 1-3 months

Urban locations often take longer due to more complex permitting processes.

Q5: Should I lease or purchase brewery property?

A: This depends on your financial situation and long-term plans:

Leasing Advantages:

- Lower initial capital requirement

- Flexibility if business needs change

- Landlord may cover some improvements

- Typical lease: 5-10 years with renewal options

Purchasing Advantages:

- Long-term cost savings

- Building equity

- Complete control over modifications

- Potential real estate appreciation

Many successful breweries start by leasing and purchase property after establishing profitability.

Q6: How close is too close to competing breweries?

A: Contrary to intuition, brewery clusters can be beneficial. Research shows that brewery districts often attract more overall customers than isolated locations. However, consider:

- Different beer styles reduce direct competition

- Unique experiences (food, atmosphere, events) create differentiation

- Market saturation point: Most markets can support one brewery per 20,000-25,000 people

Q7: What location factors affect brewing equipment costs?

A: Several location-related factors impact equipment expenses:

- Shipping and logistics: Remote locations increase delivery costs (10-25% more)

- Installation complexity: Difficult site access raises installation costs

- Custom configurations: Space constraints require customization (add 15-30%)

- Utility adaptations: Equipment modifications for local utilities

- Local codes: Specialized equipment for regulatory compliance

Working with experienced manufacturers like HGMC who offer comprehensive services helps minimize these costs through efficient planning and design optimization.

Q8: Can I relocate a brewery if the first location doesn’t work?

A: While possible, brewery relocation is extremely expensive and disruptive. Costs typically include:

- Equipment dismantling: $30,000-100,000

- Transportation: $20,000-80,000

- Reinstallation: $50,000-150,000

- Lost production: Revenue loss during 2-4 month transition

- Licensing: New permits and approvals

Best practice: Invest time in thorough location analysis upfront to avoid costly relocations.

Key Takeaways: Making the Right Location Decision

Choosing the right location for your craft brewery is a complex decision that will impact every aspect of your business for years to come. Here are the essential points to remember:

✓ Prioritize the fundamentals: Water quality and quantity, electrical capacity, and wastewater capabilities are non-negotiable requirements.

✓ Balance costs and opportunities: Urban locations offer market access but higher costs; rural locations provide affordability but require creative marketing.

✓ Plan for growth: Choose locations with 30-50% expansion capacity beyond your initial needs.

✓ Understand local regulations: Zoning, licensing, and environmental regulations vary dramatically by location and can make or break your project.

✓ Match equipment to location: Work with experienced manufacturers who can customize brewing systems to your specific site requirements.

✓ Consider your business model: Taproom-focused breweries need high-traffic locations; production breweries need efficiency and distribution access.

✓ Analyze the complete picture: Use data, industry research, and professional consultation to evaluate locations objectively.

Partner With Industry-Leading Equipment Manufacturers

Once you’ve selected the ideal location for your craft brewery, the next critical step is choosing the right brewing equipment partner. HGMC brings decades of experience and innovation to brewery projects worldwide.

As the world’s leading manufacturer of beer brewing equipment, HGMC produces:

- Brewery equipment for all scales (micro to large production)

- Beverage equipment for diversified product lines

- Canning and bottling lines for efficient packaging

With more than 30 national authorized patents and more than 20 high-tech achievements, HGMC has established itself as an innovation leader in brewing technology.

Comprehensive Service Approach

HGMC provides a full range of services tailored to your location’s unique requirements:

Individual Equipment Solutions:

- Custom-designed systems for space-constrained locations

- Equipment modifications for specific utility configurations

- Specialized components for unique climate conditions

Turnkey Projects:

- Complete brewery design and installation

- Site-specific engineering and planning

- Integration of all systems and components

- Training and ongoing support

Global Experience, Local Expertise

With successful installations exported to more than 120 countries, HGMC brings unparalleled experience adapting brewing equipment to diverse:

- Geographic and climate conditions

- Building configurations and constraints

- Utility infrastructure variations

- Regulatory and compliance requirements

- Cultural and market preferences

This global experience, combined with recognition and praise from customers worldwide, makes HGMC the ideal partner for breweries at any location—from dense urban centers to remote rural areas.

Conclusion

The success of your craft brewery begins with selecting the right location. By carefully evaluating market access, infrastructure requirements, regulatory environment, and growth potential, you can choose a site that sets your business up for long-term success.

Remember that location and equipment are intrinsically connected—your site’s characteristics will significantly influence brewing system design, configuration, and costs. Partnering with experienced professionals who understand both location analysis and equipment customization is essential.

Whether you’re planning a small urban brewpub or a large-scale production facility, the principles outlined in this guide will help you make informed decisions. Take the time to analyze multiple locations thoroughly, consult with industry experts, and plan for future growth.

The perfect location for your craft brewery is out there—armed with this knowledge, you’re ready to find it.

For more information about brewery equipment solutions customized to your specific location requirements, contact HGMC’s expert team. With proven success in more than 120 countries and comprehensive service capabilities, HGMC can help transform your brewery vision into reality—regardless of where you choose to build.