In recent years, the global beer market has changed rapidly. Craft breweries, regional brands, and large industrial breweries are all looking for more efficient, reliable, and flexible brewing solutions. In this context, Turnkey Brewery Systems have become an attractive choice for many investors and brewers who want to reduce project risks and speed up time to market.

HGMC is the world’s leading manufacturer of beer brewing equipment. We produce brewery equipment, beverage equipment, and canning/bottling lines. We have more than 30 national authorized patents and more than 20 high‑tech achievements. We provide a full range of services, including individual equipment and turnkey projects. All products are in compliance with the ISO9001:2015 quality management system, exported to more than 120 countries in the world, and have won recognition and praise from customers.

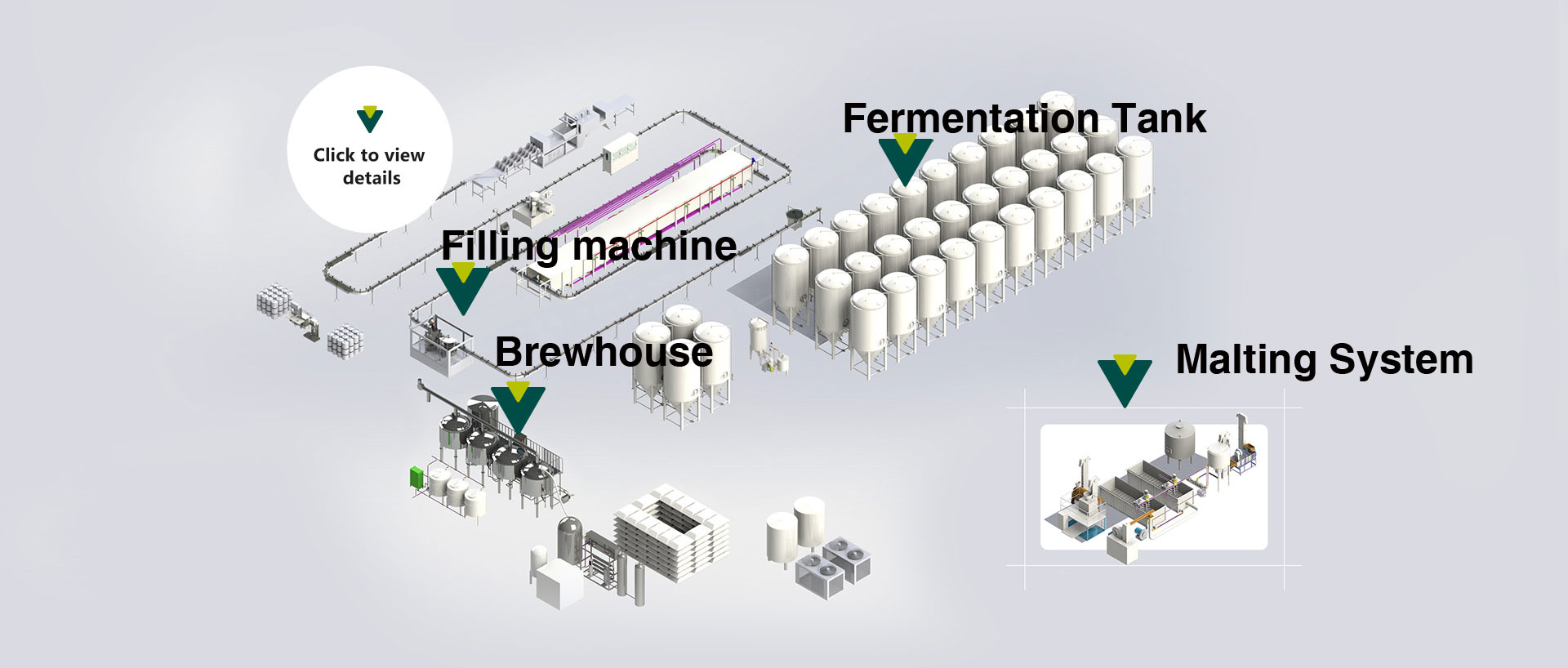

From small commercial breweries to large industrial plants, HGMC offers complete Turnkey Brewery Systems with capacities ranging from 100L to 200T, covering all key processes: malting, mashing, fermentation, filling, sterilization, labeling, and packaging. Our goal is simple: make your production process efficient, energy‑saving, and controllable, so you can produce any type of beer and quickly build a strong position in your market.

1. What Is a Turnkey Brewery System?

Before investing in a new production line, many customers ask a key question: “What is a Turnkey Brewery Machine and How Does It Work?”

A Turnkey Brewery System is a complete, integrated brewing solution supplied by one professional manufacturer. “Turnkey” means that most of the engineering work is done by the supplier. The customer receives an almost ready‑to‑run system that can be put into production after installation, commissioning, and basic training.

In practical terms, a turnkey brewery system usually includes:

- Design of the overall brewing process and plant layout

- Brewhouse, fermentation, and cellar equipment

- Cleaning‑in‑place (CIP) systems and utilities integration

- Filling, sterilization, labeling, and packaging lines

- Automation and control systems for monitoring and operation

- On‑site installation, commissioning, and operator training

For the investor or brewery owner, a turnkey solution reduces the need to coordinate multiple suppliers and technical teams. It shortens the project schedule, lowers communication risk, and provides a clear responsibility for system performance.

2. What Is a Turnkey Brewery Machine and How Does It Work?

When people search online for “What is a Turnkey Brewery Machine and How Does It Work?”, they want to understand both the concept and the actual operation. Below is a simplified explanation based on HGMC’s engineering practice.

2.1 Main Functional Modules

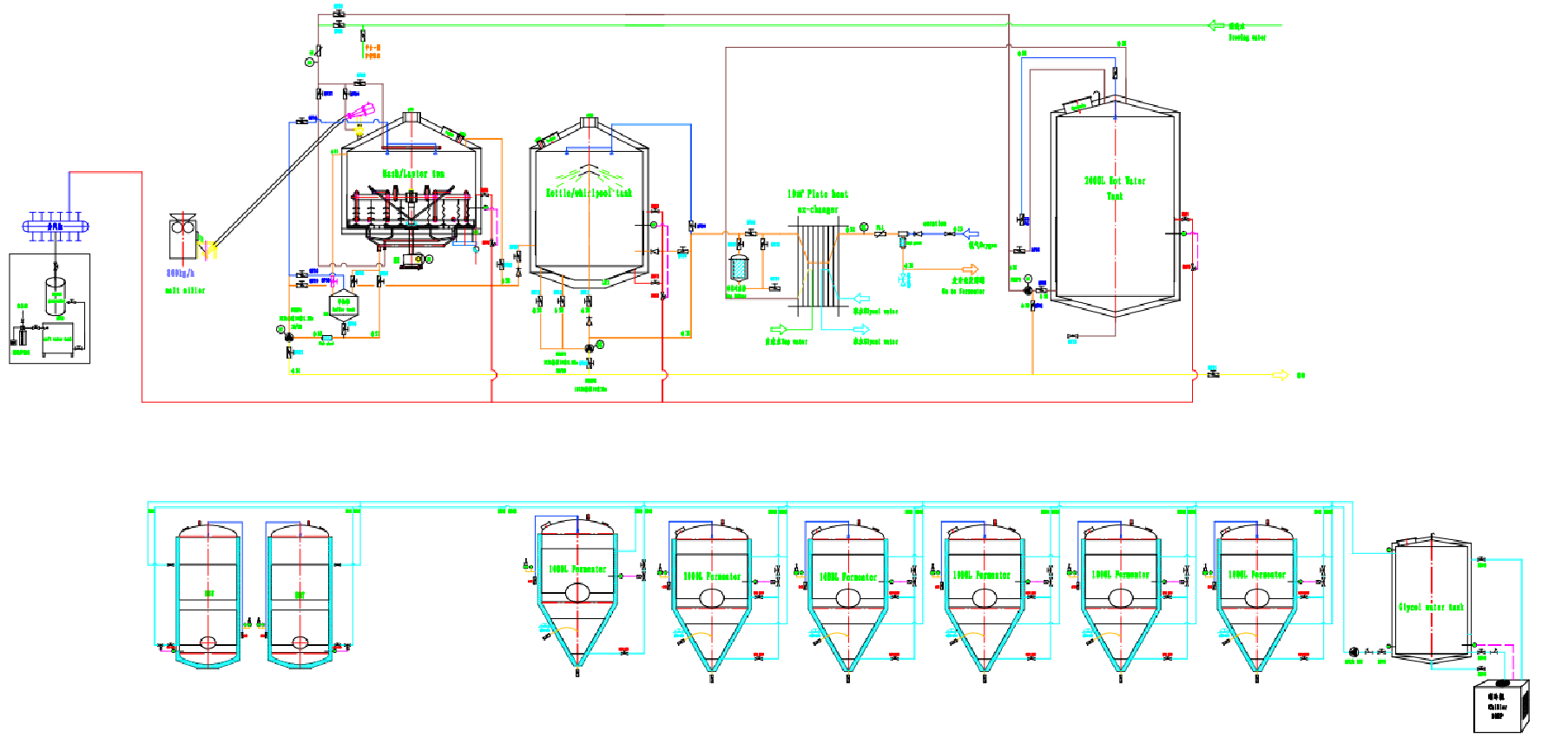

A typical Turnkey Brewery Machine or system from HGMC is built around several functional modules:

- Malting and Raw Material Handling

- Handling of malt or other grains

- Milling systems with controlled particle size

- Conveying systems to the brewhouse

- Mashing and Lautering

- Mash tun with precise temperature control and mixing

- Lauter tun designed for efficient wort separation

- Automation to control step mashing processes

- Boiling and Whirlpool

- Wort kettle for boiling, hop additions, and sterilization

- Whirlpool for removing trub and creating clear wort

- Energy‑saving heating systems and vapour management

- Fermentation and Maturation

- Cylindroconical fermentation tanks (CCTs) with cooling jackets

- Bright beer tanks for conditioning and carbonation

- Temperature and pressure control for consistent quality

- Filling, Sterilization, and Packaging

- Bottle and can rinsing and sterilization units

- Filling machines with high accuracy and low oxygen pickup

- Capping and seaming equipment

- Labelers, date coders, and packaging conveyors

- Cleaning and Utilities

- CIP systems for automatic cleaning and disinfection

- Cooling systems, steam systems, air supply, and water treatment

- Central control panel or PLC system for integrated operation

2.2 How It Works in Daily Production

In daily operation, a Turnkey Brewery Machine works as an integrated production line:

- Raw material preparation – Malt or grains are milled to the required size.

- Mashing – Crushed malt is mixed with water and heated through programmed steps. Enzymes convert starches into fermentable sugars.

- Lautering – Wort is separated from spent grain through the lautering system. The design of the lauter tun directly affects efficiency and clarity.

- Boiling and whirlpool – Wort is boiled with hops for bitterness, flavor, and aroma, then transferred to the whirlpool for trub separation.

- Cooling and fermentation – Hot wort is cooled and sent to fermentation tanks, where yeast converts sugars into alcohol and CO₂, creating beer.

- Maturation and clarification – Beer is conditioned, clarified, and, if needed, filtered to achieve the desired taste and appearance.

- Filling and packaging – Finished beer is filled into bottles or cans, sterilized as required, labeled, coded, and packed for distribution.

Because the whole system is designed and supplied by one manufacturer, the interfaces between each step are fully considered. This is the core value of a Turnkey Brewery System: smooth integration, predictable performance, and easier management.

3. HGMC’s Turnkey Brewery Systems: From 100L to 200T

Every brewery has different needs, so HGMC offers a wide capacity range for Turnkey Brewery Systems, from small pilot or commercial systems to large industrial production lines.

3.1 Small and Medium Commercial Breweries (100L–20T)

For start‑ups, brewpubs, and regional craft breweries, HGMC designs compact and flexible systems:

- Brewhouse sizes from 100L to several thousand liters

- Modular fermentation tanks that can be added as demand grows

- Semi‑automatic or fully automatic control, depending on operator skills

- Space‑saving layouts suitable for restaurants, bars, and limited industrial units

These systems allow breweries to produce a wide variety of beer styles while controlling investment. With HGMC’s Turnkey Brewery Systems, small and medium breweries can achieve professional production standards from the first day.

3.2 Large Industrial Breweries (20T–200T)

For large industrial breweries, capacity, energy efficiency, and reliability are the main focus. HGMC provides:

- Large‑scale brewhouses up to 200T per brew

- High‑capacity fermentation and bright beer tanks

- Efficient heat recovery and cooling systems

- Fully automated process control and monitoring

- Integrated bottling and canning lines designed for continuous operation

These high‑capacity systems are designed for stable, long‑term operation with strict quality control. They can produce lager, ale, specialty beer, and non‑alcoholic beer, meeting the needs of large distribution networks.

4. Complete Beer Production: From Malting to Packaging

One of the strengths of HGMC is the ability to provide a complete set of beer production equipment, including:

- Malting – Handling of malt, milling, and preparation

- Mashing – Process design for different recipes and beer styles

- Fermentation – Proper tank design for controlled fermentation and maturation

- Filling – Bottling and canning lines matched to your capacity

- Sterilization – Pasteurization and other methods as required

- Labeling – Labeling machines compatible with various container types

- Packaging – Conveyors, carton packing, and palletizing interfaces

Because we design the full chain, our Turnkey Brewery Systems are efficient and energy‑saving. Utilities like cooling water, steam, and compressed air are calculated based on actual needs, reducing waste and operating costs. This integrated approach makes your production process simple, controllable, and easy to scale.

5. Technology, Patents, and High‑Tech Achievements

Behind each HGMC system is a strong base of research and development. Our team continues to improve tank structures, piping layouts, automation functions, and energy‑saving solutions.

- More than 30 national authorized patents

- More than 20 high‑tech achievements

- Ongoing projects in new materials, process optimization, and automation

These achievements are not just technical points on paper. They appear in small but important details: a better jacket design that saves cooling energy, a more hygienic connection structure that improves cleaning, or a control function that helps brewers manage recipes more easily.

As a result, HGMC is often chosen by breweries that need authoritative and technically solid suppliers of Turnkey Brewery Systems and individual process equipment.

6. Quality Management and Global Recognition

To ensure consistent quality, all HGMC products comply with the ISO9001:2015 quality management system. From material purchasing to final testing and documentation, each step follows a clear procedure.

Key quality principles include:

- Use of food‑grade stainless steel and reliable components

- Careful welding and internal surface treatment for hygiene

- Pressure testing, leak testing, and functional testing for each tank and module

- Electrical and automation systems built according to international standards

Because of this strict quality control, HGMC’s equipment has been exported to more than 120 countries worldwide. Our customers include:

- Craft and commercial breweries

- Large industrial beer producers

- Beverage factories and co‑packing facilities

- Hotel and restaurant breweries

- Research and training centers

Over time, our systems have won recognition and praise from customers for stable performance, ease of operation, and responsive after‑sales service.

7. Full‑Range Services: More Than Just Equipment

A successful brewing project requires more than machines. It requires clear planning, correct process decisions, and reliable technical support. HGMC provides a full range of services, including:

- Project ConsultingWe listen to your ideas, budgets, and market plans, then suggest suitable capacity and configuration options.

- Process and Layout DesignOur engineers design process flows and plant layouts, including brewhouse, cellar, utilities, and packaging areas.

- Manufacturing and Quality ControlEquipment is produced under ISO9001:2015, with inspections at each stage.

- Logistics and InstallationWe coordinate packing, shipment, and on‑site installation to match your construction schedule.

- Commissioning and Trial ProductionOur engineers test each part of the Turnkey Brewery System, then assist with trial batches to fine‑tune the process.

- Training and DocumentationOperators and maintenance staff receive training on safety, daily operation, cleaning, and basic troubleshooting.

- After‑Sales Service and UpgradesWe provide long‑term technical support, spare parts, and possible upgrades as your production grows.

Because HGMC is the world’s leading manufacturer of beer brewing equipment, customers can rely on our experience in many different markets and product categories. This is especially important for breweries entering new regions or adding new beer styles.

8. Why Choose HGMC for Turnkey Brewery Systems?

When breweries compare suppliers of Turnkey Brewery Systems, several factors often decide the final choice:

- Technical strength and patents – HGMC has more than 30 patents and 20+ high‑tech achievements.

- Complete product range – From 100L pilot systems to 200T industrial lines, including malting, brewing, and packaging.

- Global project experience – Equipment installed in over 120 countries with different regulations and market needs.

- Strict quality system – All products comply with ISO9001:2015.

- Efficient and energy‑saving design – Helps reduce long‑term operating costs and environmental impact.

- Authoritative and professional support – Our engineers and project managers provide clear, practical guidance instead of only catalog information.

For investors and brewers who want a reliable, authoritative partner, HGMC offers both advanced technology and practical, real‑world solutions.

9.How Much Does a Turnkey Brewery System Cost?

Cost depends on size, automation, heating, and tank count.

General Price Guide

| Size | Cost (USD) |

| 5 bbl | $45,000 – $90,000 |

| 10 bbl | $80,000 – $150,000 |

| 20 bbl | $150,000 – $280,000 |

| 30 bbl | $250,000 – $450,000 |

| 50 bbl | $380,000 – $700,000 |

Factors that increase cost

- 4-vessel brewhouse

- Full automation

- Extra CCTs

- Steam heating

- Customized layout

- Factors that reduce cost

- electric heating

- standard configurations

- manual controls

10. Grow Your Brewery with HGMC Turnkey Solutions

Whether you are planning a small commercial brewery, upgrading an existing facility, or building a large industrial plant, a Turnkey Brewery System can greatly reduce project complexity. By working with one experienced supplier, you save time, avoid technical conflicts, and gain a clear picture of costs and performance.

HGMC’s integrated offering – from malting to packaging, from 100L to 200T – allows you to:

- Launch new products faster

- Improve consistency and quality

- Control your production costs

- Expand capacity step by step with confidence

With efficient and energy‑saving equipment, your production process becomes simple and controllable. You can focus on what truly matters: developing excellent beers, building your brand, and quickly occupying your target market.