Starting a microbrewery combines passion with precision—and your equipment decisions directly impact quality, efficiency, and profitability. With evolving technologies and market competition, selecting the right setup requires balancing science, scalability, and budget.

What is a microbrewery?

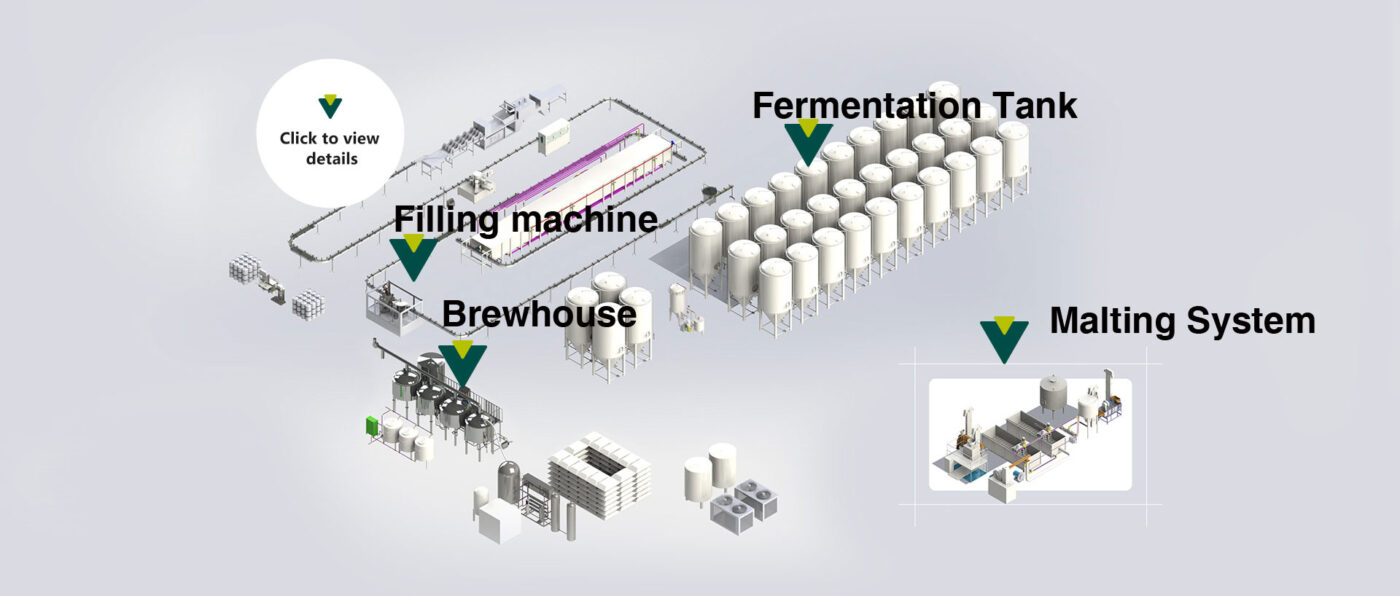

Microbrewery equipment refers to equipment used for small-scale beer production, usually with a small capacity, suitable for brewing companies, craft breweries, etc. It mainly includes a series of functions such as brewing, fermentation, storage, and packaging, and can produce high-quality beer with scarce raw materials and space.

What is Microbrewery Equipment?

Malt Mill

The crusher is the first stage in the brewing process, which is mainly used to crush the malt into particles, increase the interruption of malt contact with water, and thus promote the mash process. In Formicrobreweriesy, the crusher capacity is generally small and suitable for small-batch production.

Mash Tun

The malt after thorough crushing in the mash tank is mixed with hot water, and the starch in the malt is converted into fermentable sugars by heating. In microbrewery equipment, the mash tank is usually multifunctional. In addition to the mash function, it can also be used to filter malt residue, etc.

Boiling Kettle

The boiling kettle is used to heat the wort to a boiling state and add flower beer for boiling. Hops not only provide bitterness but also have an antiseptic effect. During the boiling process, the flavor and aroma of hops will blend with the wort to form the basic flavor of beer.

Cooling Equipment

In the beer brewing process, cooling is a key link, which directly affects the flavor, quality, and smooth progress of the beer brewing process. Rapidly reduce the wort temperature after boiling to ensure that the yeast can reproduce healthily. The design and selection of cooling equipment are related to the final quality of beer.

Fermentation Tank

The fermentation tank is used to cool the boiled wort and add yeast for fermentation. The yeast sugar is converted into alcohol and concentrated to complete the fermentation process. For micro-brewing equipment, the capacity of the fermentation tank can be adjusted according to production needs. Generally, there are single tanks and double tanks (such as primary fermentation tanks and secondary fermentation tanks).

Bright Tank

The beer storage tank is used for secondary fermentation, clarification, and maturation of fermented beer. This process usually improves the precision of the beer and improves the clarity and taste of the beer. The beer storage tank is very important for the quality control of beer. In micro-breweries, the control of the beer storage process often determines the quality of the finished beer.

Packaging equipment

In micro-breweries, beer packaging usually includes bottling, canning, or barreling. The variety and function of packaging equipment are diverse, which can meet the packaging needs of different bottle sizes and forms. Suitable packaging equipment can ensure that the quality of beer is not affected by oxidation or contamination while improving production efficiency.

Advantages of Hgmc’s micro-brewing equipment

Shandong HG Engineering Equipment Co., Ltd. is the world’s leading manufacturer of beer brewing equipment. We produce brewery equipment, beverage equipment and canning/bottling lines. We have more than 30 national authorized patents and more than 20 high-tech achievements. We provide a full range of services, including individual equipment and turnkey projects. All products are in compliance with the ISO9001: 2015 quality management system, exported to more than 120 countries in the world, and have won recognition and praise from customers.

We provide a complete set of beer production equipment, including malting, mashing, fermentation, filling, sterilization, labeling, and packaging. With capacities ranging from 100L to 200T, it can meet the needs of small commercial breweries as well as large industrial breweries. Our equipment is efficient and energy-saving, which makes your production process simple and controllable, can produce any type of beer, and help you quickly occupy the market.

Low investment cost

Compared with large-scale industrial brewing equipment, the investment cost of micro-brewing equipment is lower, which is suitable for small enterprises or home brewers. For those who are the first to enter the field of beer production, the investment cost of micro-brewing equipment is low, which gives more people the opportunity to enter this industry.

Flexible and diversified production

Micro-brewing can support small-scale and diversified production equipment. Brewers can adjust the recipe of beer according to demand, try different brewing processes or innovate beer flavors, and meet the market’s demand for personalized and customized beer.

Small space requirements

Micro-brewing equipment is small in scale and has relatively low space requirements. Small breweries can flexibly choose the site and adapt to different types of geographical environments such as cities or villages, which makes micro-brewing equipment an ideal choice for some urban craft beer bars or pubs.

Improve beer quality

Due to the small scale of production, micro-breweries must pay more attention to quality control in each production workshop. Peanut brewers can adjust and optimize according to the details of the brewing process to ensure the flavor and quality of beer. At the same time, resulting in lower output, beer can often be produced with first-class quality standards and is favored by the market.

Finally Choose equipment—and a partner—that helps your craft stand out, batch after batch.

Internal references for more detail:

3000L Brewery Equipment

2000L Brewery Equipment

1000L Brewery Equipment

800L Brewery Equipment

300L Brewery Equipment