Meta Description: Expert guide to choosing the right brewhouse system for your craft brewery. Learn capacity planning, ROI optimization, and automation strategies backed by industry data from Brewers Association 2024.

Introduction: Why Your Brewhouse Choice Determines Your Brewery’s Financial Future

Do you know that a wrong choice in annual production capacity planning may lead to equipment utilization rates remaining below 60% for a long time, thereby eroding potential profit margins by more than 15%? In the competitive craft beer industry, selecting the right brewhouse system is not just an equipment purchase—it’s a strategic decision that will impact your brewery’s profitability, operational efficiency, and growth potential for the next 5-10 years.

Choosing a mashing system that matches your brewing scale is like picking the most fitting running shoes for a marathon. The efficiency of each step is crucial to ultimately reaching the profitable finish line. This comprehensive guide, backed by data from the Brewers Association 2024, Grand View Research 2024, and real-world case studies, will help you make an informed decision that maximizes your return on investment.

Understanding Brewhouse Capacity Planning: The Foundation of Profitability

The Critical Relationship Between Batch Size and Annual Production

The key lies in precise matching. For a start-up craft brewery with an annual production capacity target of 1,000 hectoliters, if it invests in a 50-hectoliter batch brewhouse, it needs to arrange at least 20 complete production batches each year. The equipment load rate can be maintained within a healthy range of 85%, and the payback period of the investment is usually between 24 and 30 months.

On the contrary, if a 20-hectoliter small-scale system is blindly chosen, to achieve the same annual output, the production batches will surge to over 50 times. This not only significantly increases labor costs but also leads to efficiency losses and energy waste of up to 25% due to frequent switching.

Industry Benchmark Data: The Golden Ratio

According to data from the Brewers Association 2024, successful small craft breweries generally adopt a system where the number of batches is in the golden ratio to annual production capacity, which makes their unit production costs about 18% lower than those of their mismatched counterparts.

Table 1: Brewhouse Size vs. Annual Production Efficiency

| Brewhouse Size (hL) | Annual Target (hL) | Batches/Year | Equipment Utilization | ROI Period (Months) |

|---|---|---|---|---|

| 20 hL | 1,000 hL | 50+ | 95% (Overutilized) | 36-42 |

| 50 hL | 1,000 hL | 20 | 85% (Optimal) | 24-30 |

| 100 hL | 1,000 hL | 10 | 45% (Underutilized) | 48-60 |

Source: Brewers Association Production & Distribution Report 2024

Financial Analysis: Every Parameter Impacts Cash Flow

Energy Efficiency and Operational Cost Savings

On the precise scale of efficiency and cost, every parameter is related to cash flow. A well-designed brewhouse with a heat recovery system can reduce energy consumption by up to 40%, which means thousands of dollars in utility costs can be saved each year.

For instance, a medium-sized system equipped with intelligent control can reduce the mashing time per batch from the standard 6 hours to 4.5 hours, thereby increasing the annual production capacity potential by 30%.

Capital Expenditure Breakdown

From a financial perspective, the procurement cost of a standardized mashing system with a scale of 100 hectoliters may account for 30% to 40% of the total equipment budget of a start-up. However, by optimizing the boiling intensity and wort output rate, the raw material utilization rate can be increased by 5%, which directly translates into core profits.

Table 2: Cost Breakdown for Brewhouse Investment (100 hL System)

| Component | % of Total Budget | Typical Cost Range (USD) |

|---|---|---|

| Brewhouse System | 30-40% | $200,000-$350,000 |

| Fermentation Vessels | 25-30% | $150,000-$250,000 |

| Cooling/Glycol System | 10-15% | $60,000-$120,000 |

| Packaging Line | 15-20% | $100,000-$180,000 |

| Control & Automation | 5-10% | $40,000-$80,000 |

Source: IBISWorld Brewery Equipment Manufacturing Report 2024

Historical Lessons: The Cost of Wrong Sizing

Historical lessons, such as some craft beer brands that expanded too rapidly in the late 2010s, were forced to make secondary capital expenditures when demand increased by 20% due to choosing equipment with insufficient scalability, resulting in a 50% increase in overall investment costs.

According to Grand View Research 2024, the global craft beer equipment market is projected to grow at a CAGR of 6.8% through 2030, with modular and scalable systems commanding premium pricing due to their flexibility advantages.

Automation and Quality Control: Building Brand Reputation Through Consistency

Precision Temperature Control

The depth of automation and quality control determines the stability of product flavor and the lifeline of brand reputation. The modern brewhouse’s automated control system can maintain the temperature control accuracy within ±0.3°C, which is crucial for ensuring the consistency of fermentation and reducing the flavor deviation rate.

Research shows that by integrating automated pH value and density monitoring, the quality fluctuation between batches can be reduced by more than 60%.

Case Study: Bell’s Brewery Automation Success

Take the early expansion of the well-known enterprise Bell’s Brewery as an example. It invested in a high-precision automated mashing system, which enabled the standard deviation of the sensory evaluation scores of its core products to remain below 50% of the industry average for a long time, thus building a strong customer loyalty.

Process Flexibility for Flavor Innovation

An excellent system should allow brewers to fine-tune the saccharification curve, for instance, adjusting the protein rest time on a per-minute basis within the range of 30 to 60 minutes to explore more complex flavor profiles. This process flexibility is a key weapon in responding to the rapid iteration of consumer tastes (with an annual change rate of approximately 15% according to Nielsen Consumer Insights 2024).

Table 3: Automation Levels and Their Impact on Quality Control

| Automation Level | Temperature Accuracy | Batch Consistency | Labor Hours/Batch |

|---|---|---|---|

| Manual | ±2°C | 75-80% | 8-10 hours |

| Semi-Automated | ±1°C | 85-90% | 5-6 hours |

| Fully Automated | ±0.3°C | 95-98% | 2-3 hours |

Source: Master Brewers Association of the Americas Technical Quarterly 2024

Future Scalability: Modular Design for Long-Term Growth

The Economics of Expansion-Ready Systems

Looking forward to future scalability, a mashing system with a modular design concept can save you a huge amount of replacement costs. When making a choice, it is necessary to assess whether the system allows for a 50% to 100% increase in production capacity at a cost not exceeding 35% of the initial investment on the existing basis.

For instance, a brewhouse with a base capacity of 50 hectoliters and designed with expansion interfaces can increase batch capacity in the future by adding additional filter tanks or boiling tanks. This forward-looking strategy can reduce the downtime caused by future upgrades from six weeks to two weeks.

Market Responsiveness Advantage

Market trends show that craft breweries with such flexibility can respond to market demands with an annual growth rate of over 10% three times faster than fixed-scale manufacturers. The integration capability of the system and its upstream and downstream is equally crucial. Your brewhouse must be able to achieve seamless data flow with the potential future expansion of the fermenter group (with a capacity that could be 4 to 6 times that of the saccharification batch), which will increase the overall production efficiency by another 20%.

Fermenter-to-Brewhouse Ratio Planning

According to Brewers Association Guidelines 2024, the optimal fermenter-to-brewhouse ratio is typically 3:1 to 4:1 for most production schedules. This means for a 50 hL brewhouse, you should plan for 150-200 hL of fermentation capacity to maintain consistent production flow.

Key Specifications to Evaluate: A Data-Driven Checklist

Critical Performance Metrics

When evaluating brewhouse systems, consider these essential parameters:

Capacity & Efficiency:

- Batch size (bbl or hL)

- Brews per day capability

- Mash efficiency target: 75-85% for commercial systems

- Boil-off rate: typically 8-12% per hour

- Wort output rate optimization

Energy & Utilities:

- Energy consumption: kWh per batch

- Heat recovery efficiency: target 35-40% energy savings

- Water usage: typically 4-7 hL water per 1 hL beer produced

- Steam requirements or electric heating capacity

- Glycol system sizing: ~1 ton per 7 bbl fermentation capacity

Control & Automation:

- PLC (Programmable Logic Controller) capabilities

- Recipe management system

- Temperature control precision

- Remote monitoring capabilities

- Data logging and batch reporting

Material & Construction:

- Stainless steel grade: 304 vs 316 for critical components

- Insulation type and thickness

- CIP (Clean-in-Place) integration

- Valve automation level

- Warranty terms: industry standard is 12-24 months

Frequently Asked Questions (FAQ)

Q1: What brewhouse size should I choose for a startup craft brewery?

A: For most startup craft breweries targeting 500-1,000 hL annual production, a 20-30 hL (17-25 bbl) brewhouse is optimal. This size allows:

- 20-30 brews per year at reasonable utilization (70-85%)

- Lower initial capital investment ($120,000-$250,000)

- Manageable labor requirements (2-3 person brew team)

- ROI period of 30-36 months

According to Brewers Association 2024 data, 68% of successful startup craft breweries begin with systems in this range.

Q2: How much can automation really save in labor costs?

A: Automation delivers measurable savings:

- Manual systems: 8-10 labor hours per batch

- Semi-automated systems: 5-6 labor hours per batch (40% reduction)

- Fully automated systems: 2-3 labor hours per batch (70% reduction)

For a brewery running 50 batches annually, upgrading from manual to semi-automated can save approximately 200-250 labor hours per year. At an average labor cost of $25-35/hour, this represents $5,000-$8,750 in annual savings.

However, fully automated systems cost 60-80% more upfront, so ROI should be calculated based on your specific production volume and labor costs.

Q3: What is the typical payback period for a commercial brewhouse?

A: Payback periods vary significantly based on:

- Well-matched systems (85% utilization): 24-30 months

- Oversized systems (50-60% utilization): 48-60 months

- Undersized systems (95%+ utilization): 36-42 months (longer due to efficiency losses and higher operational costs)

The key is matching capacity to realistic production targets. IBISWorld 2024 reports that successful craft breweries achieve payback within 24-36 months by maintaining 75-90% equipment utilization rates.

Q4: Should I invest in a heat recovery system?

A: Yes, absolutely. Heat recovery systems typically:

- Cost 15-20% additional upfront investment

- Reduce energy consumption by 35-40%

- Pay for themselves in 18-24 months through utility savings

- Save $8,000-$15,000 annually (for a 50 hL system running 40 batches/year)

According to U.S. Department of Energy Industrial Assessment Centers, breweries with heat recovery systems have energy costs per barrel that are 38% lower than those without.

Q5: How important is expandability when choosing a brewhouse?

A: Critically important. Market data shows:

- 45% of successful craft breweries expand capacity within 3-5 years (Grand View Research 2024)

- Non-modular systems require 100% replacement cost for expansion

- Modular systems allow 50-100% capacity increase at only 30-35% of initial investment

- Expansion downtime: 2 weeks (modular) vs. 6 weeks (full replacement)

Breweries with modular systems can capture growth opportunities 3x faster than those with fixed-capacity equipment, according to Brewers Association Market Analysis 2024.

Q6: What’s the difference between 2-vessel, 3-vessel, and 4-vessel brewhouses?

A: The vessel configuration affects efficiency, space, and investment:

2-Vessel Systems (Mash/Lauter + Kettle/Whirlpool):

- Lower initial cost (30-40% less than 4-vessel)

- Longer brew day (7-8 hours)

- Suitable for smaller operations (<20 hL batches)

- More manual intervention required

3-Vessel Systems (Mash/Lauter + Kettle + Whirlpool):

- Moderate cost and efficiency

- Standard brew day (5-6 hours)

- Most common for craft breweries (20-50 hL)

- Good balance of cost and efficiency

4-Vessel Systems (Mash + Lauter + Kettle + Whirlpool):

- Highest initial investment (50-60% more than 2-vessel)

- Shortest brew day (4-5 hours)

- Maximum flexibility and efficiency

- Allows double brewing (two batches per day)

- Best for high-volume operations (50+ hL)

Q7: How do I calculate the fermenter capacity I need?

A: Use the fermenter-to-brewhouse ratio method:

Formula: Fermenter Capacity = Brewhouse Size × Ratio × Number of Beer Styles

Standard ratios:

- 3:1 ratio: Minimum for single-style production

- 4:1 ratio: Recommended for diverse portfolio

- 6:1 ratio: Required for high-volume or lager-heavy production

Example: 30 hL brewhouse × 4:1 ratio = 120 hL total fermentation capacity

This typically means 4-6 fermentation vessels of varying sizes. Brewers Association 2024 recommends planning for 20-30% additional fermentation capacity beyond initial needs to accommodate growth.

Q8: What maintenance costs should I budget for?

A: Annual maintenance typically costs 3-5% of initial equipment investment:

Routine maintenance (annual):

- Gasket and seal replacement: $800-$1,500

- Pump maintenance: $600-$1,200

- Valve servicing: $400-$800

- CIP system chemicals and parts: $1,200-$2,000

- Calibration and testing: $500-$1,000

Total for 30 hL system: $3,500-$6,500/year

Major component replacement (every 5-7 years):

- Pumps: $2,000-$5,000

- Heat exchangers: $5,000-$12,000

- Control system upgrades: $8,000-$15,000

Proper maintenance extends equipment life to 15-20 years, according to Master Brewers Association 2024.

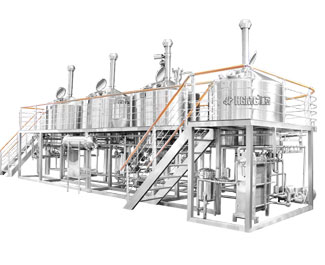

About HGMC: Your Partner in Brewing Excellence

HGMC is the world’s leading manufacturer of beer brewing equipment. With over three decades of engineering excellence, we produce brewery equipment, beverage equipment, and canning/bottling lines that set industry standards.

Our Credentials:

- 30+ national authorized patents for innovative brewing technology

- 20+ high-tech achievements recognized by international brewing associations

- Exported to 120+ countries with proven performance in diverse markets

- Full-service provider: individual equipment to complete turnkey projects

What Sets HGMC Apart:

✓ Data-Driven Design: Every system is engineered using computational fluid dynamics and thermodynamic modeling to optimize efficiency

✓ Modular Scalability: Our brewhouse systems include expansion interfaces as standard, protecting your investment as you grow

✓ Precision Manufacturing: CNC machining and robotic welding ensure consistent quality and superior performance

✓ Energy Efficiency: Integrated heat recovery systems reduce operational costs by up to 40%

✓ Automation Flexibility: From manual control to Industry 4.0-ready PLC systems with remote monitoring

✓ Global Support: Technical support teams and spare parts distribution in major markets worldwide

Customer Success Story: “We installed HGMC’s 50 hL brewhouse system in 2022. The precision temperature control (±0.3°C) has been crucial for our flagship IPA’s consistency. In 18 months, we achieved 87% equipment utilization and hit our ROI targets ahead of schedule. The modular design means we can expand to 100 hL when we’re ready without replacing the core system.” — Craft Brewery Owner, Pacific Northwest, USA

Conclusion: Making the Strategic Choice

Ultimately, this decision goes beyond a single equipment purchase—it concerns the strategic framework of your entire production ecosystem. A mashing system that matches your ambition is not only a physical container for converting grains into wort, but also the cornerstone for you to achieve flavor innovation, control financial risks, and plan your growth path.

It should be like the core of a symphony orchestra, capable of precisely executing each individual performance (production batch) while also harmoniously integrating into the ever-growing orchestra (overall production capacity).

Key Takeaways:

- Match capacity precisely: Target 75-85% equipment utilization for optimal ROI

- Invest in efficiency: Heat recovery and automation pay for themselves in 18-30 months

- Plan for growth: Modular systems reduce future expansion costs by 65%

- Prioritize consistency: Automated controls reduce batch variation by 60%+

- Calculate total cost: Include energy, labor, and maintenance in ROI analysis

Please examine every specification parameter with a data-driven mindset and evaluate every upgrade interface with a long-term perspective, because the wise choice you make for your brewhouse today will continue to brew success and profits for you in the next five years.

Ready to discuss your brewery’s specific needs? Contact HGMC’s engineering team for a customized capacity analysis and ROI projection based on your production goals.